Surface roughness is a critical aspect in evaluating how materials interact with their environment, impacting everything from mechanical performance to visual aesthetics. Two essential metrics used to quantify surface roughness are RA (Roughness Average) and RMS (Root Mean Square). Although both RA and RMS are derived from the surface profile’s peaks and valleys, they utilize these measurements in distinct ways.

How RA and RMS Are Measured

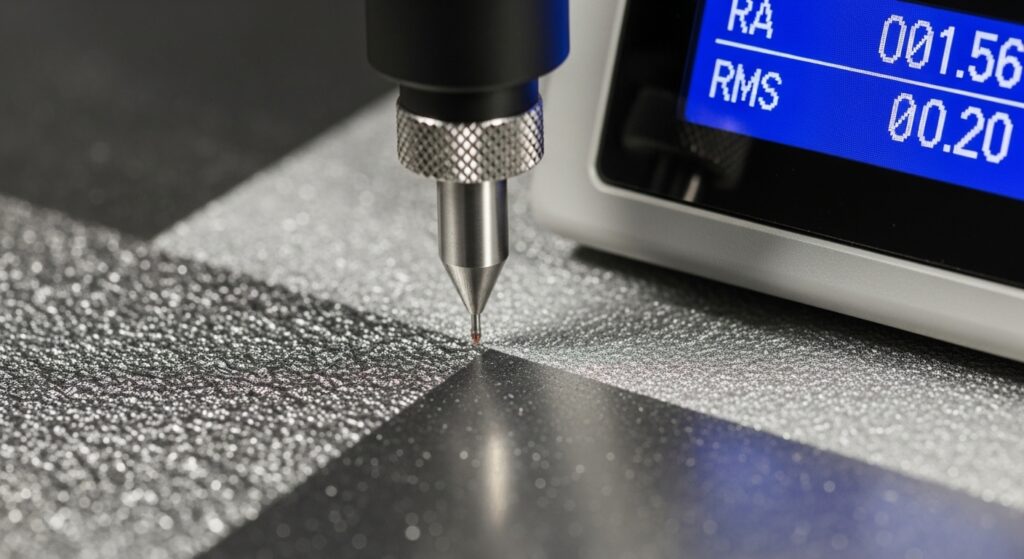

Both RA and RMS measurements are conducted using a device known as a profilometer, which tracks and records the minute variations along a surface’s profile. Despite their similar methodologies in data collection, the mathematical calculations applied to derive RA and RMS values differ significantly, influencing how each measurement is interpreted and used.

Differences Between RA and RMS

- RA: Roughness Average RA, or the arithmetic average roughness, is calculated by averaging the absolute values of the surface height deviations from the mean line, recorded along the measurement length. This parameter is especially useful because it provides a straightforward, averaged value that represents the general roughness of a surface. It’s typically less influenced by extreme peaks or valleys, making it a stable measure for general surface texture.

- RMS: Root Mean Square RMS takes a different approach by focusing on the square root of the average of the squared deviations of the surface heights from the mean line. This method means that RMS is more sensitive to pronounced peaks and troughs on a surface profile. Because of this sensitivity, RMS can provide a more accurate reflection of surface irregularities that might affect mechanical processes like friction or wear.

Practical Implications of Surface Roughness

The physical characteristics of a surface, such as its roughness, directly influence how the material will behave in its operational environment. Here are some key aspects:

- Friction and Wear Rougher surfaces typically exhibit higher levels of friction, which can lead to increased wear over time. This is particularly crucial in applications such as bearing surfaces and mechanical seals where smooth operations are critical.

- Adhesion On the other hand, rougher surfaces can improve adhesion. This is beneficial in applications such as paint adherence or in adhesive bonding processes where a greater surface area and mechanical interlocking are desired.

- Aesthetic and Functional Coatings Surface roughness also affects the application of coatings, whether for protective or aesthetic purposes. A surface’s roughness needs to be appropriately matched to the coating process to ensure proper adhesion and finish quality.

Significance of RA and RMS in Industry

Understanding the nuances between RA and RMS allows engineers and materials scientists to make more informed decisions about material selection and processing techniques. For instance, in highly precise engineering fields like aerospace and automotive manufacturing, controlling surface roughness is essential for ensuring the reliability and efficiency of component parts. Similarly, in the semiconductor and electronics industries, surface smoothness can significantly influence manufacturing outcomes and product performance.

By accurately measuring and analyzing RA and RMS, industries can optimize the durability, functionality, and efficiency of their products, thereby enhancing performance and extending the lifespan of their applications.

Why Accuracy in Surface Roughness Matters

Surface roughness plays a vital role in determining how materials perform, interact, and endure in their intended applications. By measuring key parameters, such as RA and RMS, engineers and manufacturers gain valuable insights into the texture and quality of surfaces—insights that directly influence decisions in product design, functionality, and reliability.

While RA offers a simple, averaged view of surface texture, RMS provides greater sensitivity to variations that could impact performance-critical components. Together, these metrics enable precise control over surface characteristics in industries ranging from aerospace to electronics. As technologies advance and demands for material precision grow, accurate surface roughness measurement will remain a cornerstone of quality assurance, innovation, and competitive advantage.

Are you a manufacturer or producer seeking surface roughness testing?

Contract Laboratory’s improved platform can help. Submit a lab request and find an outsourcing partner quickly and easily.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.