In an era defined by high-resolution sensors and advanced imaging, the performance of any optical system—from medical endoscopes and astronomical telescopes to consumer cameras and semiconductor lithography—is entirely dependent on the quality of its glass and lenses. Unlike architectural or container glass, optical glass requires perfection at the micro-level. A microscopic bubble, a slight variation in the refractive index, or contamination that compromises material purity can render a high-value component useless. Therefore, rigorous optical glass analysis and lens testing are not just quality control steps; they are fundamental requirements for achieving specified image fidelity and system performance. This article details the specialized themes and laboratory protocols used to ensure that optical glass meets the exacting demands of modern science and technology, confirming flawless light transmission and eliminating all optical defects.

Optical Glass Analysis: Verifying Refractive Index and Light Transmission

The primary function of any optical element is to precisely manipulate light. Two critical material properties—refractive index and light transmission—must be quantified and verified to ensure the lens or prism bends light exactly as designed and without undue energy loss.

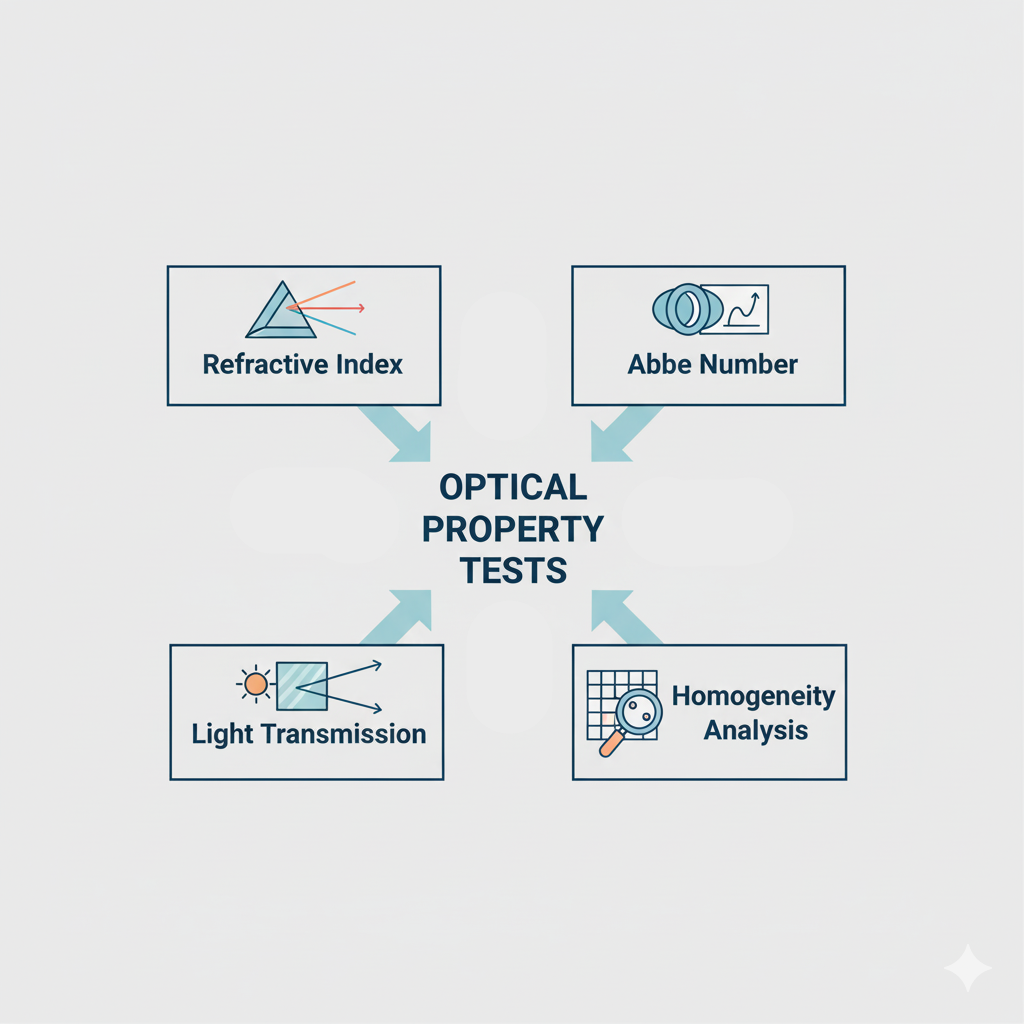

Essential Optical Property Tests:

- Refractive Index (n) Measurement: This is the most fundamental test in optical glass analysis. The refractive index determines how much light is bent (refracted) when passing through the material. Precise instruments, such as high-accuracy refractometers, are used to measure the index at various standardized wavelengths (e.g., d-line, C-line, F-line). This data is essential for calculating chromatic aberration and verifying the glass batch against design parameters.

- Abbe Number (Vd) Determination: Closely related to the refractive index, the Abbe number measures the dispersion of the glass—how much the index changes with wavelength. A higher Abbe number indicates lower dispersion, which is critical for correcting chromatic aberrations in multi-element lens testing.

- Light Transmission (Spectral Transmission): This test measures the percentage of light that passes through the material across a range of wavelengths (from UV to near-IR). High light transmission is required to maximize image brightness and system efficiency. Coatings (like anti-reflective coatings) are tested to ensure they minimize reflection and maximize transmission within the application’s required spectral band.

- Homogeneity Analysis: Even slight variations in refractive index within a single blank of glass can introduce wavefront errors. Interferometry and specialized optical glass analysis techniques are used to map the refractive index across the entire block, ensuring exceptional uniformity (homogeneity) down to 10−6 level.

These precise measurements guarantee the material’s optical characteristics match the theoretical design, a non-negotiable step in high-fidelity lens testing.

Material Purity Testing: Chemical Composition and Trace Element Verification

The smallest impurities or inclusions within the glass matrix can act as light scatterers, degrading image quality and compromising laser integrity. Achieving high material purity is a continuous challenge, making rigorous compositional analysis a cornerstone of optical glass analysis.

Methods for Assessing Purity and Composition:

- Inclusion and Bubble Analysis (Visual and Automated): Bubbles, or “seeds,” and solid inclusions, or “stones,” scatter light and reduce overall visual quality. Samples are inspected under specialized high-intensity dark-field illumination. Automated image analysis systems quantify the size, frequency, and location of these optical defects according to strict quality standards (e.g., ISO 10110).

- Trace Element Analysis (ICP-MS): High-sensitivity techniques like Inductively Coupled Plasma Mass Spectrometry are used to profile elemental composition and detect trace contaminants (e.g., iron, copper). These elements, even in parts-per-million concentrations, can significantly reduce light transmission in the UV or IR ranges.

- Striation (Striae) Detection: Striations are minute, ribbon-like non-uniformities in the refractive index within the glass, caused by uneven mixing during the melting process. Interferometric and schlieren photography methods are used during optical glass analysis to identify and map these defects, which cause localized image distortion.

- Coloration and Solarization Testing: Colorimetry measures the inherent color of the glass. Solarization testing assesses the material’s stability under prolonged exposure to high-energy radiation (such as UV light), ensuring that the glass does not change color or lose light transmission over time, particularly critical for space or extreme environment applications.

Verifying material purity and eliminating micro-defects are critical steps that protect the high precision of the refractive index and ensure maximum light transmission.

Lens Testing: Assessing Mechanical Strength and Environmental Durability

While optical performance is paramount, lenses and windows must also withstand the physical rigors of mounting, machining, and operational environments, especially in military, industrial, or medical settings. Lens testing must verify physical strength without compromising the sensitive optical surfaces.

Durability and Environmental Test Protocols:

- Surface Scratch and Abrasion Resistance: Coatings applied to lenses (like AR or protective coatings) are tested for durability using standardized friction tests (e.g., pencil hardness or severe abrasion tests with controlled rubbing). This ensures the surface remains undamaged during cleaning and handling, protecting the light transmission properties.

- Adhesion Testing (Cross-Hatch Test): For coated lenses, the adhesion of the thin-film layers to the glass substrate is checked. A pattern of cuts is made into the coating, and an adhesive tape is applied and removed. The amount of coating removed determines the adhesion rating, ensuring the coating resists delamination.

- Thermal Shock and Environmental Cycling: Lenses used in outdoor or aerospace environments are subjected to rapid changes in temperature and humidity. Lens testing involves cycling the components (e.g., from −40∘C to +80∘C) to ensure that the glass, coatings, and mounting bond lines do not fail or induce stress that leads to cracking or degradation of the refractive index.

- Chemical Resistance: Components intended for medical or laboratory use (e.g., endoscopes) must withstand sterilization or strong cleaning agents. Testing measures the material’s resistance to corrosion, staining, or etching when exposed to specified chemicals.

These mechanical and environmental tests are vital for ensuring the longevity of the component and maintaining its performance integrity after installation.

Precision Quality Control: Detecting Optical Defects and Surface Flaws

The final visual quality inspection is a comprehensive check that aggregates all previous data, confirming that the finished lens or blank is free from critical macroscopic and microscopic optical defects. Even if the refractive index is perfect, surface flaws can severely degrade image quality.

Metrics for Optical Defect Identification:

- Surface Quality (Scratch-Dig): This is a critical specification that limits the size and frequency of cosmetic surface flaws. The scratch-dig standard (e.g., US MIL-PRF-13830B or ISO 10110-7) uses comparison standards to grade the acceptable width of scratches and diameter of ‘digs’ (pits or small craters). Tight scratch-dig specifications are mandatory for high-power laser and high-magnification applications.

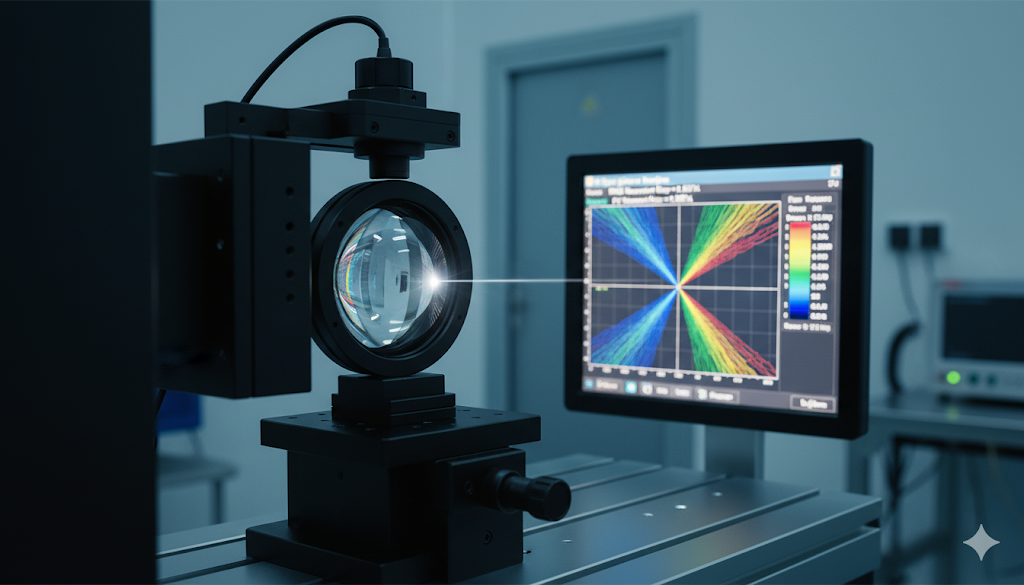

- Wavefront Error (Interferometry): The most precise measure of a lens’s fidelity. Interferometers measure how much the light wave deviates from a perfect sphere after passing through the lens. The result is expressed in wavelengths (λ), with very high-quality lenses often requiring errors of λ/10 or less. This test identifies subtle aberrations and residual optical defects missed by simpler checks.

- Centering and Thickness Variation: Geometric precision is tested by measuring the center thickness, edge thickness variation, and the centration (alignment) of the optical axis relative to the mechanical axis. Poor centration is a common source of image distortion and asymmetry.

- Strain Birefringence: Polariscopic analysis is used to detect residual internal stress (strain) in the glass, which can alter the refractive index locally, leading to birefringence (double refraction). Stress management, particularly in molded optics, is essential for maintaining high visual quality.

Meticulous optical glass analysis and lens testing against these standards guarantee that the final component performs at the peak of its engineering specification, ensuring true visual quality.

Achieving Flawless Visual Quality Through Comprehensive Optical Glass Analysis

The complexity of modern optical systems demands testing far beyond simple visual quality inspection. Comprehensive optical glass analysis provides the quantitative data required to guarantee core parameters, including precise refractive index values, high light transmission efficiency, and confirmed material purity. Specialized lens testing protocols—from measuring wavefront error to verifying trace elements—are essential to ensure components are free from performance-degrading optical defects and are robust enough for their intended environments. Partnering with independent laboratories offers the advanced instrumentation and expertise necessary to validate these critical characteristics, ensuring that a system’s glass components match its technological ambition.

Submit a testing request today to secure project integrity with reliable, third-party laboratory verification.

FAQ

The refractive index is the most critical optical parameter as it dictates the bending of light. Precise measurement during optical glass analysis is necessary to calculate the focal length, curvature, and required thickness of the lens, ensuring the finished optical system focuses light accurately and minimizes geometric aberrations.

High material purity is essential because trace metallic impurities (like iron) can cause absorption, and inclusions (optical defects) like bubbles or stones cause scattering. Both absorption and scattering reduce the total amount of light passing through the component, compromising light transmission and lowering the system’s efficiency.

Scratch-dig is a specification used in lens testing to quantify acceptable levels of surface flaws (scratches and pits). While these defects may seem minor, they can significantly scatter light, especially in high-magnification or high-power laser applications, leading to beam damage or reduced visual quality and contrast.

The Abbe number is a derived value that quantifies the material’s light dispersion. It relates to the refractive index by measuring how much the index changes across different wavelengths. This is vital for designing achromatic lenses that correct for chromatic aberration (color fringing), a key concern in high-quality imaging.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.