While often considered purely aesthetic, ceramic tiles and the more durable porcelain tiles are high-performance engineering materials. Their success in flooring, wall applications, and external cladding is entirely dependent on performance metrics established through rigorous ceramic tile testing. From guaranteeing pedestrian safety in commercial kitchens to ensuring material integrity on a building’s exterior through freeze-thaw cycles, the role of specialized testing cannot be overstated. Manufacturers, importers, and architects rely on verified data concerning slip resistance, water absorption, abrasion resistance, and overall durability testing to ensure products meet required building codes and performance specifications. Ignoring these tests can lead to dangerous conditions, product failures, and costly liabilities down the line. This comprehensive article outlines the core testing themes essential for maintaining quality, safety, and longevity in the flooring industry.

Ensuring Pedestrian Safety: The Crucial Role of Slip Resistance Testing

Of all the protocols involved in ceramic tile testing, assessing slip resistance is arguably the most critical for public and commercial applications. Slips, trips, and falls are a leading cause of accidental injury, making verified traction data paramount for safety compliance. Testing must quantify the friction provided by the tile surface, both when dry and when contaminated with water or other common liquids.

The industry relies on a specific metric known as the Dynamic Coefficient of Friction (DCOF), which measures the resistance encountered when a person is in motion.

Key Slip Resistance Testing Methods:

- DCOF Measurement (ANSI A326.3): This is the modern standard used in North America. The DCOF instrument measures the instantaneous friction provided by a floor surface when a specific force is applied. A higher DCOF value (e.g., typically 0.42 or higher for level indoor spaces) indicates greater slip resistance.

- Wet Pendulum Test (ASTM E303): Used globally, the pendulum test simulates a heel striking a wet floor. A weighted foot swings across the surface, and the height of the subsequent swing is measured. The resulting Pendulum Test Value (PTV) correlates directly to the slip potential.

- R-Value Test (Ramp Method – DIN 51130): Widely used in Europe, this test involves a person walking on an oil-coated tile ramp while the angle of inclination is gradually increased. The angle at which the person slips determines the R-rating (ranging from R9, low resistance, to R13, high resistance). This test is crucial for industrial or wet environments.

- Barefoot Ramp Test (DIN 51097): Similar to the R-Value test, but performed barefoot on a water-coated ramp, specifically for pool surrounds, showers, and spa areas. This test ensures the tile maintains safety in persistently wet, barefoot conditions.

Comprehensive slip resistance analysis must be conducted on the tile as it will be used—new, wet, and often after simulated wear—to accurately predict long-term safety performance.

Quantifying Longevity: Abrasion Resistance and Durability Testing

For any flooring material, the ability to withstand daily wear—foot traffic, heavy furniture, cleaning chemicals, and embedded dirt—determines its lifespan and aesthetic viability. Abrasion resistance is a measure of a tile’s surface toughness and is essential for specifying the correct product for high-traffic zones.

Assessing Abrasion Resistance (PEI Rating):

For glazed ceramic tiles, the widely recognized test uses the Porcelain Enamel Institute (PEI) scale, which classifies tiles based on their resistance to surface wear:

| PEI Class | Application Area | Expected Foot Traffic |

|---|---|---|

| PEI 0 | Walls/Decor | No foot traffic (for walls only) |

| PEI 1 | Very Light | Barefoot traffic, specific residential bathrooms |

| PEI 2 | Light | General residential areas excluding kitchens/entrances |

| PEI 3 | Moderate | All residential areas and light commercial (offices) |

| PEI 4 | Heavy | All residential, medium commercial (restaurants, shops) |

| PEI 5 | Very Heavy | Intense traffic (malls, airports, public areas) |

The PEI test involves simulating foot traffic using abrasive materials and measuring the point at which the glaze shows visible wear. This test is a fundamental part of ceramic tile testing for any flooring application.

Durability Testing for Unglazed and Porcelain Tiles:

Unglazed tiles, including most full-body porcelain tiles, require different methods as their color and composition are consistent throughout the body.

- Tabor Abrasion Test (ASTM C1243): This test uses weighted, abrasive wheels to simulate aggressive wear over the surface, quantifying the material loss over a specified number of cycles. It provides a reliable measure of inherent wear resistance for unglazed materials.

- Scratch Hardness (Mohs Scale): While not purely a durability testing method, the Mohs hardness test determines the tile’s resistance to surface scratching, which is important for maintaining visual quality in commercial settings where abrasive dirt or grit may be present.

By combining PEI or Tabor data with scratch hardness, manufacturers can provide accurate long-term performance predictions, reinforcing consumer confidence in their product’s durability testing results.

Environmental Resilience: Analyzing Water Absorption and Freeze-Thaw Resistance

A tile’s ability to resist moisture penetration is the single most important factor determining its suitability for wet areas (bathrooms, pools) and outdoor environments subject to freezing temperatures. Water absorption directly relates to porosity, which varies significantly between standard ceramics and dense porcelain tiles.

The standard ceramic tile testing procedure involves weighing the tile, boiling it in water for a set period, and then reweighing it. The percentage increase in weight is the water absorption rate.

Water Absorption Classifications (ANSI A137.1):

| Classification | Water Absorption Rate (by weight) | Typical Application |

|---|---|---|

| Non-Vitreous | >7.0% | Indoor, low-moisture areas only |

| Semi-Vitreous | 3.0% to 7.0% | Indoor, general residential use |

| Vitreous | 0.5% to 3.0% | Heavy-duty indoor/outdoor, general porcelain tiles |

| Impervious | ≤0.5% | Exterior applications, submerged areas (e.g., pool tiles) |

Freeze-Thaw Resistance:

This is a critical follow-up to water absorption testing. If a tile absorbs too much moisture (above 0.5%), the water inside the pores can freeze, expand, and shatter the tile’s structure.

- Freeze-Thaw Cycling (ASTM C1026): Tiles are saturated with water and subjected to repeated cycles of freezing (e.g., to −15∘C) and thawing. After a defined number of cycles, the tiles are examined for cracking, spalling, or loss of structural integrity. Only tiles with an impervious or highly vitreous rating should pass this crucial durability testing protocol, ensuring they are suitable for outdoor use.

Thorough analysis of water absorption is essential for preventing material failure and mold growth in high-humidity or exterior installations.

Quality Control: Assessing Dimensional Integrity and Structural Load

Beyond the wear and environmental resistance, the physical consistency and intrinsic strength of the tile body itself are critical for both installation efficiency and long-term structural performance. Dimensional conformity ensures that tiles fit together neatly with uniform grout joints, preventing costly installation errors and visual quality issues.

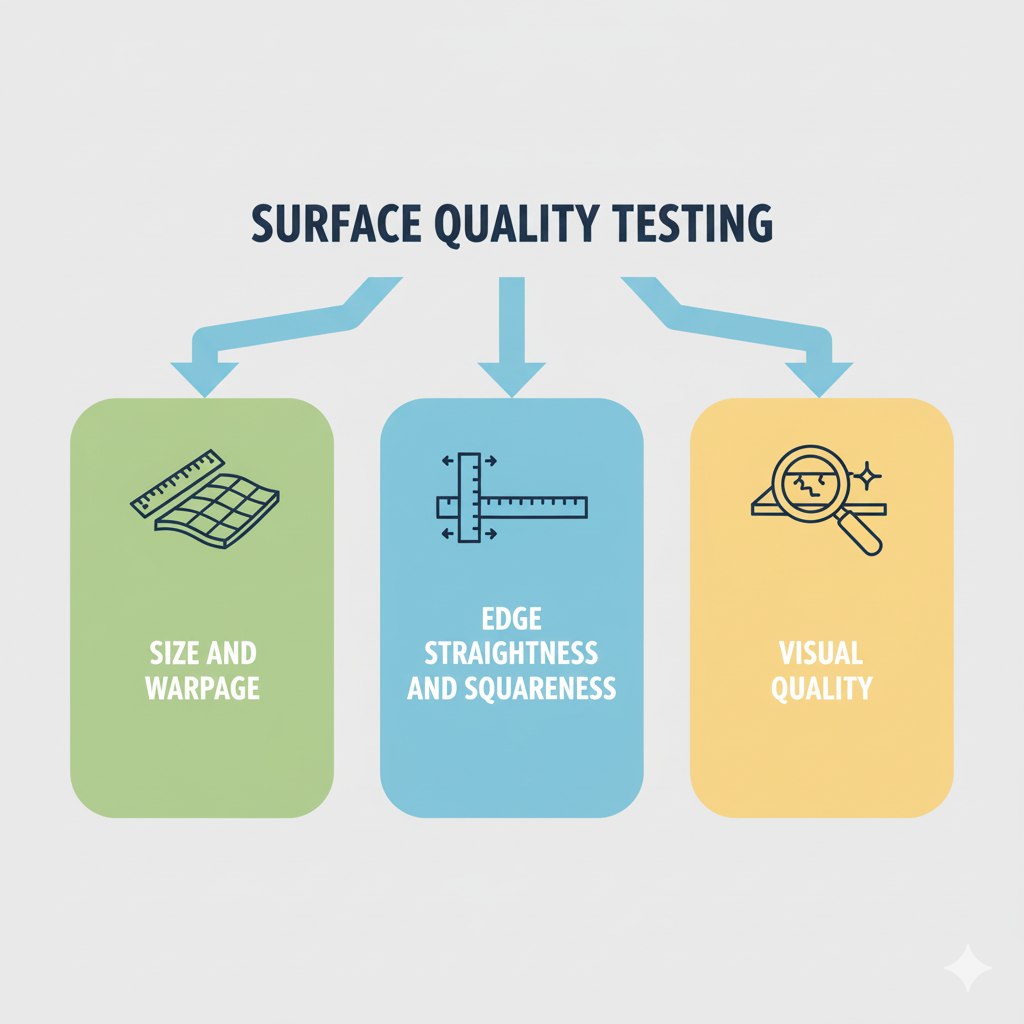

Dimensional and Surface Quality Testing:

- Size and Warpage: Digital measuring devices and feeler gauges are used to check if the length, width, and thickness of the tiles fall within the specified manufacturing tolerances. Excessive warpage (convexity or concavity) can cause “lippage”—uneven tile edges—which is a major safety and aesthetic concern.

- Edge Straightness and Squareness: These tests ensure the tiles can be laid with precise, straight grout lines. Deviations indicate issues in the pressing or firing process.

- Visual Quality Inspection: Tiles are inspected under specified lighting conditions for defects such as pinholes, specks, glaze skips, or color variations that would detract from the overall appearance and fail to meet client expectations.

Structural Load Testing:

The tile body must be strong enough to withstand the loads applied during handling, transport, installation, and daily use.

- Breaking Strength and Modulus of Rupture (MOR) (ASTM C648): This is a direct test of the tile’s load-bearing capacity. Tiles are placed on supports and a force is applied until they break.

- Breaking Strength is the maximum load the tile can withstand.

- MOR measures the internal stress the tile can handle before structural failure. High-density porcelain tiles are expected to have significantly higher values in both categories compared to standard ceramic materials. This confirms the material’s structural role and contributes to overall durability testing.

These rigorous quality control protocols confirm that every batch of material provides consistency, ensuring that the structural and aesthetic intent of the project is realized.

Driving Confidence with Data-Backed Tile Performance

From verifying slip resistance to withstand heavy traffic to quantifying water absorption to ensure freeze-thaw survival, ceramic tile testing is an indispensable process that underpins the safety and longevity of built environments. Manufacturers and project teams that proactively invest in third-party laboratory verification for porcelain tiles and other ceramic products gain the data necessary to guarantee compliance with international safety standards and minimize future liability risks. Comprehensive durability testing, coupled with precise abrasion resistance analysis, transforms a simple building material into a reliable, certified structural component.

Submit a testing request today to secure project integrity with reliable, third-party laboratory verification.

FAQ

The Dynamic Coefficient of Friction (DCOF) is the standardized method for measuring slip resistance. A higher DCOF value (typically above 0.42 for residential and commercial indoor floors) indicates greater friction when a person is walking, meaning the tile is safer and meets required safety standards for pedestrian areas.

Suitability for outdoor use is primarily determined by water absorption and freeze-thaw resistance. Tiles must have an absorption rate of 0.5%

or less (Impervious classification), which is typical of high-quality porcelain tiles. They must then pass cyclical freeze-thaw durability testing to prove they won’t crack when exposed to cold weather.

The PEI rating (ranging from PEI 1 to PEI 5) measures a tile’s abrasion resistance—specifically for glazed ceramic tiles. A higher rating, like PEI 4 or PEI 5, indicates the tile can withstand higher levels of foot traffic and surface wear, making it suitable for demanding commercial applications.

Dimensional quality testing (measuring size, warpage, and edge straightness) is crucial because precise tile dimensions ensure easy, fast, and high-quality installation. Poorly sized tiles lead to uneven grout lines and lippage, which compromise both the aesthetics (visual quality) and the durability of the final installation.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.