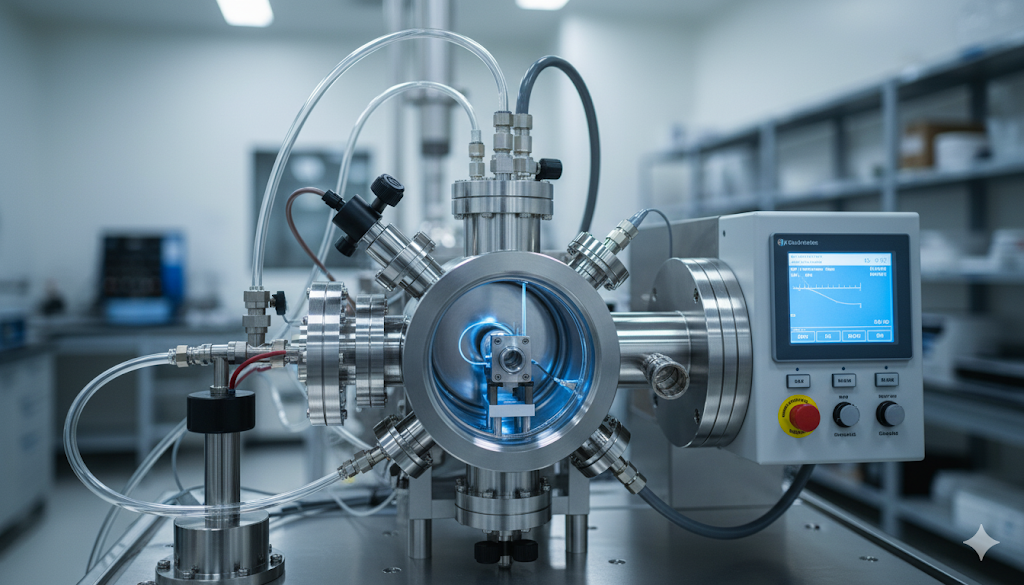

In high-reliability industries—from aerospace and medical devices to specialized electronics and vacuum technology—the failure of a single joint or seal can lead to catastrophic system failure. Unlike visible structural components, glass and ceramic seals and joints function as the “silent support,” maintaining a controlled environment and ensuring hermetic seals. This dependence places paramount importance on rigorous glass seal testing and ceramic seal testing. These specialized protocols must verify not only the initial joint integrity but also its ability to withstand extreme thermal cycling, maintain function under pressure, and confirm material compatibility over a long operational lifetime. By subjecting seals to advanced leak detection and mechanical stress tests, manufacturers gain the objective data required to mitigate risk, guarantee system performance, and comply with the most stringent industrial standards.

Verifying Hermetic Seals: Advanced Leak Detection Testing

The fundamental purpose of a seal is to prevent the unwanted passage of gases or liquids. A seal’s quality is defined by its leak rate, which must often be measured in incredibly small units (e.g., standard cubic centimeters per second). Comprehensive leak detection is therefore the primary focus of glass seal testing and ceramic seal testing.

The goal is to verify that the joint achieves true hermetic seals, critical for protecting sensitive components like microchips, laser cavities, and implantable medical devices.

Key Leak Detection Protocols:

- Helium Mass Spectrometry Leak Detection (MSLD): This is the gold standard for leak detection. The sealed component is placed in a vacuum chamber or pressurized with helium, and a mass spectrometer measures the rate at which helium (a tracer gas) permeates or leaks through the joint. This test can detect leaks down to 10−10 standard cubic centimeters per second, essential for achieving hermetic seals.

- Pressure Decay Testing: Used for larger components, this method measures the loss of internal pressure (or gain of external pressure) over a specified period. While less sensitive than MSLD, it provides a fast and reliable check for gross leaks or major breaches in joint integrity.

- Dye Penetrant Testing: For joints where liquid leakage is the main concern (e.g., automotive fluid lines), a fluorescent dye is applied to one side of the seal. After a set penetration time, the joint is examined under UV light to reveal any cracks or pathways that compromise the seal.

- Bubble Emission Testing (Gross Leak): Components are pressurized and submerged in liquid. The formation of bubbles indicates a leak pathway. This method is typically used as a preliminary check to identify major flaws before proceeding to more expensive, high-sensitivity tests.

Achieving and confirming hermetic seals through precise leak detection is the most critical step in validating joint integrity for any application involving controlled environments.

Environmental Resilience: Thermal Cycling and Stress Management

Glass and ceramics have significantly different coefficients of thermal expansion (CTE). When a joint is formed, thermal mismatch is managed to create a strong, stable bond. However, operational environments subject the seal to repeated temperature swings, which induce mechanical strain. Thermal cycling and thermal shock testing are mandatory to predict the seal’s lifespan.

Protocols for Thermal Stability:

- Thermal Cycling and Shock Resistance: This test simulates the maximum temperature range and speed of temperature change the seal will experience. Samples are repeatedly cycled between high and low-temperature extremes (e.g., −55∘C to +150∘C). The component is then re-tested using MSLD to confirm joint integrity has not been compromised by the induced stresses. This is crucial for spacecraft or deep-sea equipment.

- High-Temperature Operation (Ageing): Samples are held at or near their maximum operating temperature for extended periods (hundreds or thousands of hours). This accelerated ageing test verifies that the bonded interface does not degrade or relax over time, which could lead to gradual loss of hermetic seals.

- Vibration and Mechanical Shock Testing: Seals in aircraft, vehicles, or industrial machinery are exposed to constant vibration. Testing confirms that mechanical movement does not cause micro-fractures in the bond area. This ensures the seal maintains its joint integrity under dynamic stress, often performed concurrently with thermal cycling.

- Seal Integrity After Coating: Often, ceramic or glass components are coated or plated after the joint is formed. Tests ensure that the high heat from the coating process does not compromise the underlying bond or induce excessive residual stress, which would reduce thermal cycling resistance.

Rigorous thermal cycling and environmental testing confirm the seal’s joint integrity in real-world scenarios, extending its operational life and preventing thermal failure.

Mechanical Analysis: Assessing Joint Integrity and Bond Strength

While achieving a leak-tight connection is paramount, the joint must also possess sufficient mechanical strength to withstand handling, mounting, and operational loads (tension, shear, and torque). Ceramic seal testing and glass seal testing utilize destructive and non-destructive methods to quantify the actual strength of the bond line.

Methods for Measuring Mechanical Joint Integrity:

- Tensile and Shear Strength Testing: These destructive tests measure the force required to pull the two bonded materials apart (tensile) or slide them parallel to the joint (shear). This data is essential for design specifications and for validating the manufacturing process, ensuring consistent joint integrity across production batches.

- Torque Testing: Relevant for threaded or rotating seals, this test measures the twisting force the joint can withstand before failure. This is often applied during the assembly process to define maximum safe installation force.

- Weld Penetration and Bond Void Analysis: For certain types of ceramic-to-metal seals, X-ray inspection (radiography) or ultrasound is used as a non-destructive method to examine the bond interface for voids, cracks, or insufficient penetration, which are major threats to hermetic seals.

- Fracture Surface Analysis (Post-Failure): After destructive testing, Scanning Electron Microscopy (SEM) is used to examine the fractured surface. This allows engineers to determine the exact failure mode (e.g., cohesive failure within the glass, adhesive failure at the interface, or fracture of the ceramic body), providing invaluable feedback for material selection and design refinement.

Quantifying the physical force a joint can safely bear ensures the component can survive its application environment, confirming high joint integrity alongside hermetic seals.

Chemical and Material Compatibility Testing

A seal is only as good as the compatibility between its constituent parts (glass, ceramic, and metal). Material compatibility testing ensures that the sealing materials do not chemically react with each other or the contents they contain, especially when exposed to elevated temperatures or corrosive elements.

Essential Compatibility and Durability Checks:

- Leaching and Corrosion Testing: The seal materials are exposed to the process fluid (e.g., solvents, biological buffers, or chemical reagents) to monitor for corrosion, etching, or leaching of metallic ions. This test is vital for medical and chemical processing equipment, verifying material compatibility over time.

- Residual Stress Analysis (Polarimetry): This non-destructive test uses polarized light to detect internal stress patterns within the glass near the bond line. High residual stress, caused by poor material compatibility or an inadequate cooling rate, indicates a high risk of delayed fracture, compromising the joint integrity.

- Thermal Expansion Mismatch Verification: Laboratory techniques measure the precise coefficient of thermal expansion (CTE) of each material component (e.g., metal pin, glass frit, ceramic body) to ensure they are accurately matched or intentionally mismatched (for compression seals) to prevent early failure during thermal cycling.

- Surface Analysis (Energy-Dispersive X-ray Spectroscopy – EDX): Used in conjunction with SEM, EDX maps the elemental composition across the bond interface to verify the formation of intended reaction layers (e.g., oxides in glass-to-metal seals) that are crucial for achieving chemical adhesion and hermetic seals.

Confirming flawless material compatibility and chemical resistance is the ultimate assurance that the seal will maintain both its mechanical and hermetic seals properties throughout its long operational lifespan.

Seal and Joint Testing: The Foundation of Reliability in Critical Systems

The reliable operation of advanced technology hinges on the validated performance of its concealed connections. Comprehensive glass and ceramic seal testing provide the quantitative data necessary to verify that every component, whether maintaining a vacuum or containing hazardous material, achieves true hermetic seals. By investing in advanced protocols such as high-sensitivity leak detection, rigorous thermal cycling simulations, and detailed material compatibility analysis, manufacturers can definitively guarantee joint integrity. Partnering with specialized laboratories ensures the utilization of accredited methods, transforming the silent support components into certified, high-reliability elements that underpin overall system success.

Submit a testing request today to secure project integrity with reliable, third-party laboratory verification.

FAQ

A hermetic seal is an airtight, fusion-bonded joint that prevents the passage of gases or liquids at any measurable rate. Glass seal testing uses highly sensitive methods like helium mass spectrometry leak detection to prove the joint’s impermeability, which is essential for protecting sensitive electronics or maintaining sterile environments.

Thermal cycling subjects the seal to extreme temperature changes, causing the ceramic and bonded materials to expand and contract at different rates due to CTE mismatch. This induces stress. The test verifies that the ceramic seal testing proves the seal’s joint integrity is not compromised by these stresses, which could lead to micro-cracks and subsequent failure.

Material compatibility is crucial because the components (e.g., metal leads and glass frit) must form a strong chemical bond during the sealing process. If the materials are incompatible, the bond will be weak, leading to high residual stress, poor joint integrity, and a failure to maintain a hermetic seal over time.

Pressure decay measures the loss of pressure over time and is good for detecting large or “gross” leaks. Helium mass spectrometry leak detection (MSLD) is much more sensitive, using helium as a tracer gas to detect extremely small molecular leaks (∼10−10

atm.cc/s) that are required to verify true hermetic seals in high-reliability applications.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.