In high-risk occupational settings—from chemical processing plants and infectious disease wards to firefighting and construction—the only guaranteed barrier between a worker and catastrophic harm is the integrity of their personal protective equipment (PPE). The effectiveness of this equipment hinges entirely on rigorous, independent protective clothing testing, a mandatory process that verifies a material’s capacity to withstand the specific, life-threatening hazards it is designed to confront. Failure in protective clothing testing means failure in the field; a flawed seam in chemical gear, a compromised fabric layer in heat-resistant apparel, or insufficient cut resistance can result in severe injury or fatality. For manufacturers, distributors, and procurement teams responsible for ensuring worker safety, meticulous PPE testing is not merely a regulatory step but a core ethical and legal requirement to achieve the necessary product certification and guarantee compliance with global safety standards. This article examines the critical testing regimes required to validate these vital protective layers.

Foundational Compliance: Safety Standards and Product Certification

Before any piece of protective gear can be deployed, it must demonstrate verifiable compliance with regional and international safety standards. The landscape of PPE testing is highly codified, governed by bodies such as the Occupational Safety and Health Administration (OSHA) in the US, the European Union’s PPE Regulation (EU) 2016/425 (which leads to the CE mark), and ISO international standards. Compliance with these rules culminates in product certification, which legally validates the item’s suitability for its intended protective function.

Protective clothing testing must often involve testing to both general and hazard-specific standards. For instance, a garment might need to meet general requirements for material integrity and specific standards for chemical resistance. Failure to conduct the correct testing or obtain the appropriate product certification can lead to immediate market exclusion, penalties, and, most critically, user exposure to unacceptable risk.

Essential Steps in PPE Product Certification:

- Hazard Identification: Defining the specific threat (e.g., molten metal, infectious fluid, flash fire, mechanical abrasion) the PPE must mitigate.

- Standard Selection: Identifying the mandatory safety standards (e.g., NFPA, EN, ISO) relevant to the identified hazard and region.

- Third-Party Testing: Submitting prototypes to an accredited laboratory for comprehensive PPE testing against all required criteria.

- Technical Documentation: Compiling all test reports, design specifications, and quality control procedures into a technical file necessary for the final product certification.

This regulatory framework ensures that claims of protection are based on scientific evidence, not marketing materials, placing protective clothing testing at the heart of the supply chain.

Thermal and Flame Resistance: The Fire Barrier

One of the most critical and highly regulated areas of protective clothing testing is thermal protection, primarily focused on fire resistance and resistance to radiant and convective heat. Firefighters, welders, utility workers, and refinery staff rely on flame-resistant (FR) clothing to provide crucial escape time and prevent third-degree burns. Simply being non-melting is insufficient; the fabric must not ignite, must self-extinguish quickly, and must limit the transfer of heat through the garment.

Testing for fire resistance is complex and simulates real-world heat scenarios, evaluating how the fabric reacts under intense thermal load.

Key Tests for Fire Resistance:

- Vertical Flammability Testing (e.g., NFPA 2112, ISO 15025): A fabric specimen is exposed to a flame for a set time. The test measures the time it takes for the fabric to self-extinguish (after-flame time) and the length of fabric that chars or melts (char length). Minimal after-flame and short char lengths confirm high fire resistance.

- Heat Transfer Index (HTI): Measures the time required for the inner surface of the fabric to rise by a specific temperature, quantifying the garment’s insulating capability against convective heat.

- Manikin Testing (e.g., ASTM F1930): The gold standard for flash fire protection, where a fully garmented manikin equipped with hundreds of sensors is exposed to a controlled, simulated flash fire. This provides a percentage body burn prediction, which is crucial for product certification in oil and gas industries.

- Molten Splash Resistance: For welding and foundry PPE, specialized tests measure the force required for molten material (e.g., aluminum or iron) to adhere to or penetrate the fabric, a critical element of protective clothing testing.

Achieving compliance in fire resistance requires fabrics to be inherently resistant, or treated with durable FR finishing chemicals, with the PPE testing verifying that this performance attribute remains intact even after repeated laundering.

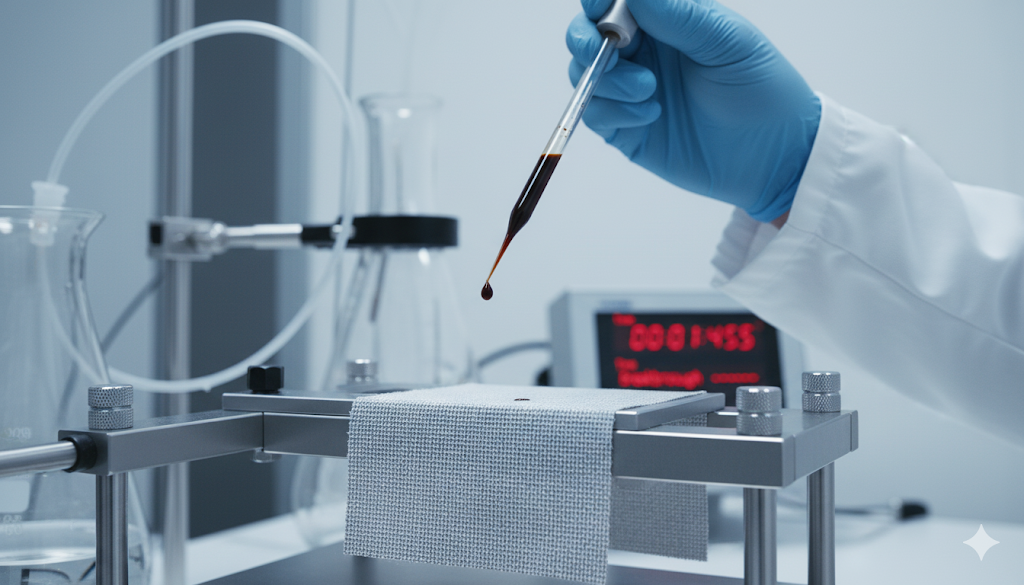

The Chemical Shield: Resistance to Permeation and Penetration

For workers handling hazardous liquids, gases, or infectious agents, the garment’s primary function is to act as an impermeable chemical shield. Chemical resistance testing determines how effectively the material prevents harmful substances from reaching the wearer’s skin or underlying clothing. This testing differentiates between two key failure modes: permeation and penetration.

- Penetration is the bulk flow of a hazardous liquid or gas through imperfections like pinholes, seams, zippers, or non-protective closures.

- Permeation is the process by which a chemical moves at a molecular level through the intact material itself—dissolving on one side and diffusing through to the other.

Rigorous chemical resistance testing is essential for both reusable and disposable PPE, including coveralls, gloves, and aprons.

Key Tests for Chemical Resistance:

| Test Method | Objective | Relevance to PPE Testing |

|---|---|---|

| Permeation Testing (ISO 6529/ASTM F739) | Measures the “breakthrough time” (the time taken for a chemical to first be detected on the inside of the fabric) and the steady-state permeation rate. | The key metric for chemical protective clothing; longer breakthrough time equals greater chemical resistance. |

| Penetration Testing (e.g., ISO 6530) | Measures the percentage of liquid chemical (e.g., sulfuric acid, sodium hydroxide) that penetrates or is repelled by the fabric. | Critical for determining splash protection and the integrity of seams and closures. |

| Viral Barrier Penetration (e.g., ASTM F1671) | Uses a surrogate virus (often a bacteriophage) under continuous pressure to test the material’s barrier effectiveness against bloodborne pathogens. | Mandatory for medical and infectious disease PPE testing to ensure chemical resistance against biohazards. |

Successful protective clothing testing for chemical resistance requires materials to be tested against the specific range of substances the end-user will encounter, ensuring the safety standards match the operational risk.

Mechanical Resilience: Cut Resistance and Durability

The mechanical integrity of protective clothing, measured through various PPE testing protocols, ensures the garment does not fail structurally under physical stress. This includes resistance to tearing, puncture, abrasion, and the highly specific requirement for cut resistance. Workers in industries like glass handling, meat processing, sheet metal fabrication, and lumber often require materials that can actively resist sharp objects.

Cut resistance testing is standardized (e.g., ISO 13997, ASTM F2992), and results are typically graded on a scale (A1 to A9 or similar) to allow users to select the exact level of protection needed for their tasks.

Key Tests for Mechanical Durability:

- Cut Resistance Testing: Measures the amount of force (in Newtons) required to cut through a sample of the material using a straight blade under a specified load. This data dictates the grade level of the cut resistance.

- Puncture Resistance: Measures the force required for a standard probe to puncture the fabric, critical for protection against needles, syringes, or sharp tools (e.g., medical gloves, waste handlers’ gear).

- Abrasion Resistance: Quantifies the material’s ability to withstand rubbing and wear over time without losing its protective function. High abrasion resistance is necessary to maintain long-term fire resistance or chemical resistance.

- Tear and Tensile Strength: Measures the force required to rip a fabric or pull it apart, ensuring the material and seams remain intact during aggressive use or struggle.

These protective clothing testing methods confirm the material’s inherent strength, confirming that the garment provides lasting durability and protection across its expected service life.

Verifying Protection and Achieving Product Certification

Effective protective clothing testing and comprehensive PPE testing are the non-negotiable prerequisites for maintaining workplace safety standards and achieving product certification. The rigorous verification of fire resistance, chemical resistance, and cut resistance is a complex, multi-layered process that requires the specialized equipment and expertise of accredited laboratories. By partnering with these experts, manufacturers can reliably ensure that their products are not just pieces of fabric, but certified protective layers—ready to defend workers against the defined hazards of their environment. This commitment to third-party verification minimizes regulatory liability, strengthens market trust, and, most importantly, saves lives.

Submit a testing request today to secure comprehensive protective clothing testing and product certification services, guaranteeing that your PPE testing meets all global safety standards for optimal user protection.

FAQ

The primary function of fire resistance testing is to ensure that the fabric does not ignite or melt, and crucially, that it self-extinguishes quickly. Protective clothing testing aims to quantify the heat transfer, which provides the critical data on how long the garment can protect the wearer from second and third-degree burns in a flash fire or arc flash scenario.

Chemical resistance testing differentiates between penetration (bulk flow through holes, seams, or imperfections) and permeation (molecular movement of the chemical through the intact fabric material). Permeation testing measures the “breakthrough time,” which is the most critical safety metric for continuous exposure PPE testing.

Cut resistance is determined in PPE testing by measuring the force (in Newtons) required for a sharp blade, under a specified load, to cut through the material. This result corresponds to a standardized numerical or alphabetical grade (e.g., A1–A9), which guides end-users in selecting the appropriate level of protection required by their safety standards.

Product certification is mandatory because it provides legal, third-party validation that the protective clothing complies with all applicable safety standards (e.g., NFPA, CE, OSHA). Without certified protective clothing testing, manufacturers and importers cannot legally claim the product provides the necessary protection, exposing them to legal liability and their users to risk.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.