The transparency and versatility of glass make it a foundational material in modern construction and automotive design, necessitating rigorous flat glass testing and laminated glass testing. The performance of these materials, particularly robust tempered glass, is directly linked to public safety, energy efficiency, and compliance with international safety standards that account for variables like thermal stress. For manufacturers and project managers, outsourcing comprehensive testing is a critical risk mitigation strategy to prevent catastrophic failure or expensive litigation. Implementing these third-party laboratory testing protocols ensures products withstand the mechanical, environmental, and optical stresses required while maintaining exceptional visual quality. This guide delves into the core themes and necessary protocols that underpin reliable glass performance, providing an actionable roadmap for specifying your next testing project.

Mechanical Integrity and Structural Durability Testing

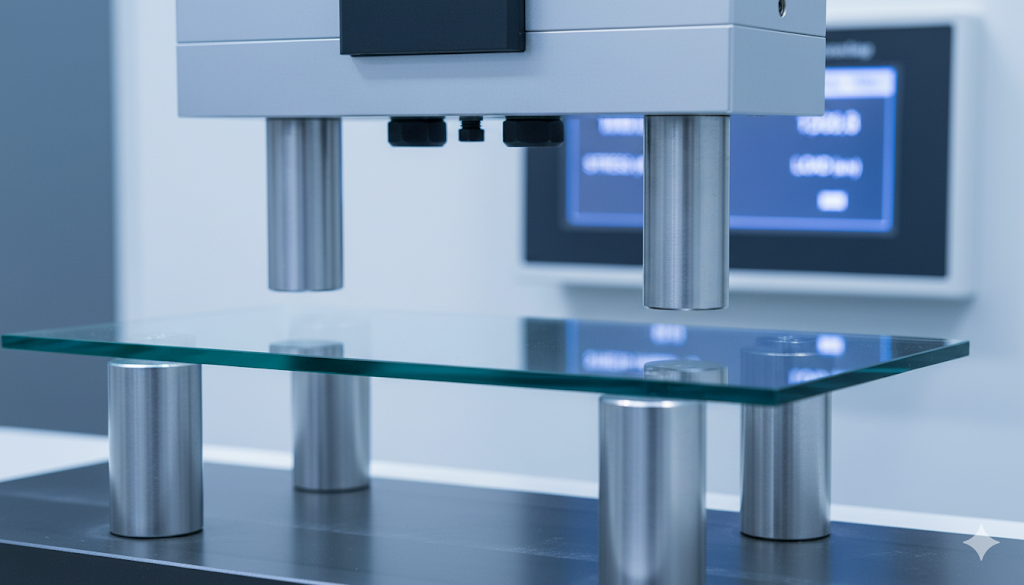

The primary function of any structural glass is to safely bear load and resist applied forces, whether from wind, impact, or static pressure. Mechanical flat glass testing protocols quantify a material’s strength, elasticity, and failure modes, providing essential data for engineering specifications. This is particularly crucial for safety glass varieties like tempered glass and laminated products.

The testing process focuses on confirming that the material’s surface compression and internal tension meet or exceed established international safety standards (e.g., ASTM, EN, ANSI).

Key Mechanical Testing Methods:

- Four-Point Bending Test: This highly accurate method measures the modulus of rupture (flexural strength) under load. It assesses the glass’s ability to resist deformation and breakage when subjected to bending stress, providing a critical measure of material integrity.

- Surface Stress Measurement (FSM): Used specifically for tempered glass and heat-strengthened glass, the FSM uses polarized light to quantify the residual surface compressive stress, ensuring the heat treatment process has been executed correctly to achieve the desired strength increase.

- Impact Resistance Testing: Simulates real-world conditions by dropping standardized weights or utilizing a pendulum to strike the glass pane. This is vital for verifying that the glass meets relevant safety codes for human impact, stone chip resistance (for automotive applications), and blast mitigation.

- Examples: Ball drop tests (for laminated glass) and shot-bag impact tests (for safety glazing).

- Edge Strength and Condition Analysis: Flaws and micro-cracks along the cut edge are the most common initiation points for fracture. Specialized tests examine the quality of grinding and polishing to minimize potential stress risers that compromise the overall strength of the pane.

Understanding these mechanical properties ensures that the flat glass specified for a facade or vehicle will maintain its structural role without unpredictable failure.

Performance Under Environmental and Thermal Stress

Glass components are rarely static; they expand, contract, and absorb energy in response to changes in temperature, humidity, and solar radiation. Testing the material’s resilience against these environmental factors is crucial, especially for insulating glass units (IGUs) and exterior glazing.

Assessing Thermal Stress and Endurance

Thermal stress is a critical factor, especially in environments with high diurnal temperature swings or when glass incorporates coatings that cause uneven heating (e.g., spandrel glass). Flat glass testing must confirm the product will not spontaneously fracture due to differential thermal expansion between heated and shaded areas of the pane.

| Testing Protocol | Objective and Relevance | Key Standard Compliance |

|---|---|---|

| Heat Soak Test (HST) | Identifies and fragments panes containing Nickel Sulfide (NiS) inclusions, preventing delayed, in-service fracture of tempered glass. | EN 14179-1 |

| Environmental Cycling | Subjecting IGUs or glass samples to repeated cycles of extreme heat, cold, and humidity to test the longevity and seal integrity of components. | ASTM E2188, E2189, E2190 |

| Solar Radiation Exposure | Accelerated aging tests using xenon arc or UV lamps to measure how ultraviolet radiation affects coatings, interlayers, and glass clarity over time. | ISO 12543-4 |

| Humidity and Condensation Resistance | Measures the material’s resistance to moisture penetration, which can cause fogging, delamination, or mold growth in the space between glass sheets. | ASTM D2247 |

By simulating prolonged exposure to harsh weather and temperature fluctuations, these tests confirm that the glass will perform reliably throughout its intended service life without issues related to thermal stress or material degradation.

Specialized Laminated Glass Testing and Safety Compliance

Laminated glass testing is a distinct and highly regulated field due to its unique construction: two or more panes of glass permanently bonded together by an interlayer (typically PVB, SGP, or EVA). This assembly is specifically designed not to shatter into large, sharp pieces upon impact, making it the industry standard for high-security, acoustic, and high-impact applications.

The key to successful laminated glass testing is verifying the adhesion between the glass and the interlayer, the post-breakage integrity, and the material’s ability to resist penetration.

Critical Laminated Glass Test Protocols:

- Boil Test (Durability and Adhesion): Glass samples are submerged in boiling water for a defined period. This stress test aggressively simulates long-term exposure to heat and moisture, revealing any weaknesses in the bond between the glass and the interlayer that could lead to bubbling or delamination in the field.

- Break Pattern Analysis: When fractured, the glass must adhere securely to the interlayer, remaining largely intact and reducing the risk of injury from flying shards. This test confirms compliance with international safety standards for overhead, barrier, and vehicular glazing.

- Penetration Resistance: This protocol, often employed for security glass or bullet-resistant products, involves high-velocity impact testing (e.g., using firearms or heavy, sharp projectiles). The goal is to verify that the laminate layers, including specialized interlayers, can absorb significant energy without catastrophic breach.

- Acoustic Insulation Measurement (STC Rating): Because laminated glass is frequently used to dampen noise, specialized sound transmission loss tests are performed to assign an accurate Sound Transmission Class (STC) rating, verifying its noise reduction performance for architectural specifications.

For applications requiring advanced safety—from public transportation to high-rise balcony railings—thorough laminated glass testing is paramount to achieving and maintaining essential regulatory compliance.

Precision Assessment of Optical and Visual Quality

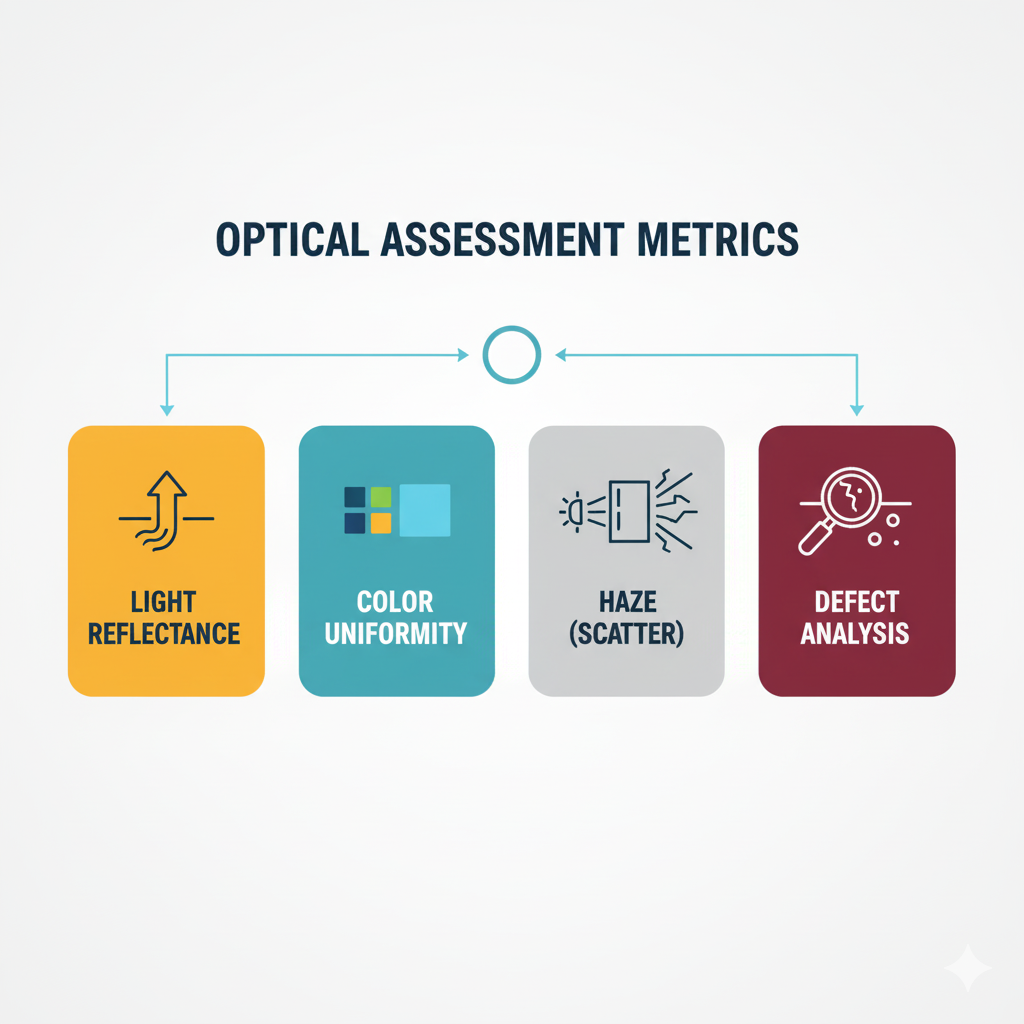

Beyond safety and structural performance, the aesthetic and functional properties of glass—its clarity, color, and optical homogeneity—are crucial for end-user acceptance and compliance with design specifications. The visual quality of the final product impacts everything from architectural sightlines to the driver’s ability to see clearly through a windshield.

Flat glass testing for optical properties requires extremely precise instrumentation and controlled environments to quantify subtle variations.

Optical and Visual Quality Assessment Metrics:

- Light Transmittance and Reflectance: Measures the percentage of light passing through the glass (transmittance) and the percentage reflected off the surface. This is essential for controlling daylighting and energy performance, particularly for low-emissivity (Low-E) coated glass.

- Color Uniformity and Delta E: Using spectrophotometers, labs measure the color of the glass and coatings against a specified standard. The resulting ΔE (Delta E) value quantifies the color difference, ensuring batch-to-batch consistency and preventing noticeable color shifts across a large installation.

- Haze and Distortion (Optical Clarity): Haze measures the amount of light scattered by the glass, which can reduce sharpness and contrast. Distortion measures unintended optical effects, such as ripples or waviness, which are common in poorly manufactured or excessively tempered glass.

- Inclusion and Defect Analysis: Glass must be inspected for physical defects, including bubbles (seeds), foreign matter (stones), and surface scratches. Specialized lighting and magnification techniques are used to map and classify these defects according to permissible standards, ensuring high visual quality.

Maintaining exceptional visual quality is essential for meeting both client expectations and prescriptive architectural specifications related to aesthetic harmony and glare control.

Ensuring Product Reliability Through Rigorous Testing

The integrity of glass, whether a standard piece of flat glass or a high-performance laminated unit, is a complex interplay of mechanical strength, thermal endurance, and optical quality. By partnering with independent laboratory experts specializing in flat glass testing and advanced laminated glass testing techniques, manufacturers and project managers gain verifiable data necessary to guarantee compliance, minimize liability, and deliver superior-performing materials. Investing in comprehensive testing for tempered glass and other glass types is the only way to proactively address risks associated with thermal stress and maintain high visual quality standards.

Submit a testing request today to secure project integrity with reliable, third-party laboratory verification.

Frequently Asked Questions (FAQ) About Glass Testing

What is the primary difference between flat glass testing and laminated glass testing?

Flat glass testing (often for annealed or tempered glass) focuses primarily on surface strength, flexural resistance, and defect analysis. Laminated glass testing focuses additionally on the adhesive properties of the interlayer, post-breakage integrity (how the broken pieces adhere), and penetration resistance, which are crucial for meeting high safety standards.

Why is testing for thermal stress so important for modern glass?

Thermal stress testing is vital because modern architectural glass often features specialized coatings (like Low-E coatings) that create high-temperature differentials across the pane’s surface when exposed to sunlight. This uneven heating can cause spontaneous fracture if the glass’s edges and surface compression are not properly manufactured and tested, especially in tempered glass.

How does flat glass testing ensure visual quality and optical clarity?

Visual quality is assessed through precise measurements of light transmission, color uniformity (ΔE values), haze (light scattering), and optical distortion. These flat glass testing metrics ensure the final product meets the specified aesthetic requirements and prevents visual anomalies, such as unwanted ripple effects or excessive glare.

Which safety standards are most commonly addressed by laminated glass testing?

Laminated glass testing commonly addresses standards related to human impact (e.g., ANSI Z97.1, EN 12600), glazing in buildings (ASTM E1300), and specific vehicle safety requirements (DOT/SAE standards). Compliance with these safety standards confirms the glass will perform as a safety barrier upon breakage.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.