The integrity of a brand that supplies home textiles and furnishings hinges on two non-negotiable pillars: quality and compliance. In a highly competitive global market, the difference between success and catastrophic recall often lies in rigorous, proactive laboratory testing. If your lab or manufacturing operation is struggling to keep pace with evolving international standards, or if you need specialized capacity to verify the performance, chemical safety, and durability of products like drapery, bedding, carpets, or upholstered furniture, mastering the comprehensive landscape of home textile testing is essential. This article will break down the critical testing categories, regulatory necessities, and actionable strategies required to maintain excellence and secure market access, ensuring your product portfolio consistently meets the stringent demands of consumer safety and regulatory bodies worldwide.

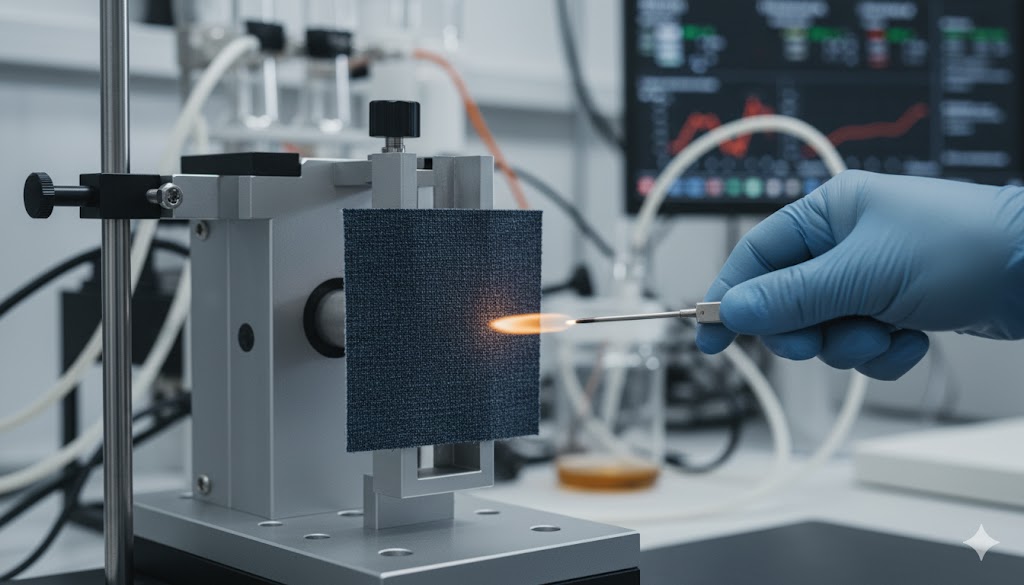

Prioritizing Flammability and Fire Safety Protocols

One of the most critical and heavily regulated aspects of home textile testing and furniture testing is flammability and fire resistance. These protocols are designed to protect consumers by ensuring that home goods, particularly those used for sleeping or seating, resist ignition and limit the rate of burn. Non-compliance in this area can lead to severe penalties, product recalls, and, most importantly, danger to the end-user. Therefore, rigorous and third-party laboratory verification of fire safety is mandatory for market entry in many jurisdictions, including the United States, Canada, and the European Union.

Key Flammability Standards

Compliance with flammability standards varies significantly depending on the product category and the target market. Labs must be proficient in conducting tests specific to different materials and end-uses.

| Product Category | Primary Test Standard (Example) | Description | Keywords |

|---|---|---|---|

| Mattresses & Bedding | 16 CFR Part 1633 (US) | Measures ignition resistance and open flame thermal output of entire mattress sets. | Mattress Flammability, Consumer Safety |

| Upholstered Furniture | TB 117-2013 (CA), BS 5852 (UK) | Evaluates the resistance of filling materials and cover fabrics to smoldering and open-flame ignition sources. | Upholstery Testing, Furniture Testing |

| Drapery & Curtains | NFPA 701 (US) | Assesses the flame propagation resistance of textiles and films used in vertical applications. | Home Textile Testing, Fire Resistance |

| Carpets & Rugs | 16 CFR Part 1630/1631 (US) | “Pill test” to determine the surface flammability of carpets and rugs. | Material Safety, Flammability |

The testing for mattress flammability, governed by standards like 16 CFR Part 1633, is particularly complex, requiring specialized testing chambers and continuous monitoring of heat release rates. Ensuring your materials—from foam cores to ticking fabrics—are tested individually and as a composite unit is vital for a successful final product analysis.

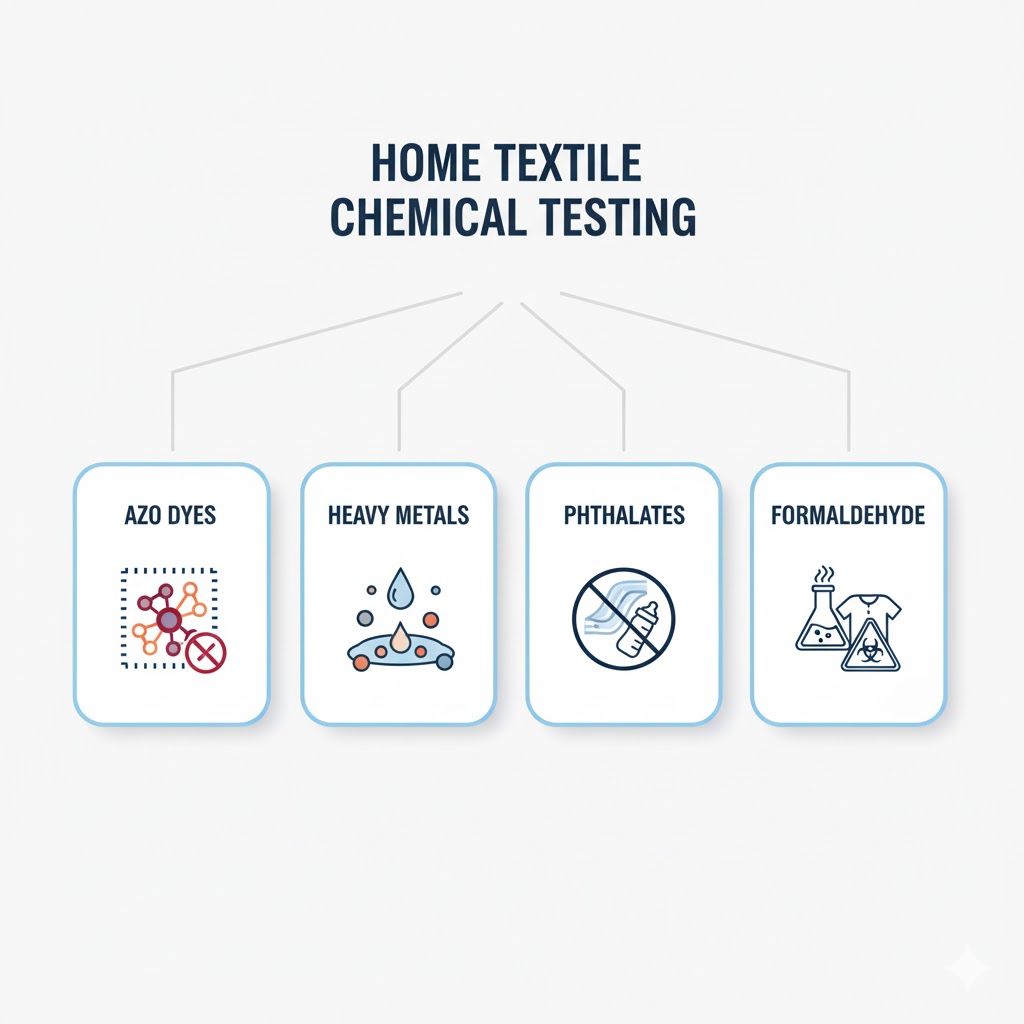

Chemical Screening and Material Safety Analysis for Textiles

Beyond performance and fire safety, the hidden chemical composition of home textiles and furnishings presents a major risk factor. Regulators globally are increasingly stringent about restricting harmful substances in products that come into close contact with consumers for extended periods. This makes advanced chemical material safety screening a critical component of home textile testing.

The presence of restricted substances, such as heavy metals, phthalates, Azo dyes, and formaldehyde, can lead to chronic health issues and immediate allergic reactions, making consumer safety paramount. A sophisticated laboratory program must include comprehensive analysis using techniques like Gas Chromatography-Mass Spectrometry (GC-MS), High-Performance Liquid Chromatography (HPLC), and Inductively Coupled Plasma Mass Spectrometry (ICP-MS) to detect trace amounts of these restricted chemicals.

Focus Areas for Chemical Testing:

- Azo Dyes: Screening for release of carcinogenic aromatic amines.

- Heavy Metals: Testing for lead, cadmium, arsenic, and mercury in dyes and finishes.

- Phthalates: Crucial for PVC and plastic components in furnishings and accessories, especially for children’s products.

- Formaldehyde Content: Testing for residual formaldehyde used in wrinkle-free finishes.

- PFCs/PFAS: Analyzing fluorinated chemicals used for water and stain repellency, now facing widespread bans.

Implementing a proactive chemical screening program that adheres to global regulations like the European Union’s REACH and various U.S. state-level prohibitions is necessary to ensure long-term market viability and uphold your brand’s commitment to material safety. This type of focused home textile testing significantly reduces the likelihood of costly recalls associated with chemical non-compliance.

Assessing Durability and Performance for Upholstery and Fabrics

While safety is paramount, consumer satisfaction is driven by the longevity and resilience of the product. Durability and performance testing are essential for ensuring that textiles and furnishings withstand typical wear and tear over their intended lifespan. For items like sofas, chairs, and carpets, this means simulating years of use through accelerated testing protocols. This is where specialized upholstery testing and performance analysis protocols provide quantifiable data on product quality.

Durability testing focuses on evaluating the physical resilience of the materials. Labs must utilize standardized equipment to measure key metrics, including:

- Abrasion Resistance: Using machines like the Martindale or Wyzenbeek apparatus to simulate rubbing and wear, crucial for upholstery testing of seating and commercial furniture fabrics.

- Tear Strength and Tensile Strength: Determining the force required to rip or break the fabric, essential for structural integrity.

- Seam Slippage: Measuring the stability of stitched seams under stress to prevent gaps and structural failure.

- Pilling Resistance: Assessing the fabric’s tendency to form pills or fuzz balls after repeated rubbing, a key aesthetic and quality indicator.

- Bursting Strength: Important for knitted fabrics, mattresses, and non-woven textiles where pressure is applied over a broad area.

By subjecting products to these rigorous furniture testing protocols, manufacturers can confidently assign performance ratings, validate warranties, and make data-driven decisions regarding material selection, ultimately enhancing product perceived value and reducing warranty claims.

Colorfastness, Dimensional Stability, and Aesthetics

The aesthetic quality of a home textile directly impacts consumer safety satisfaction and perception of quality. A faded curtain, a shrunken bedsheet, or a fabric whose dye bleeds onto other materials constitutes a product failure, regardless of its chemical or flammability compliance. Therefore, home textile testing must include a suite of tests dedicated to verifying colorfastness and dimensional stability.

Essential Aesthetic and Stability Tests:

- Colorfastness to Light: Measures how well the textile’s color resists fading when exposed to simulated sunlight over time (crucial for drapery and outdoor furnishings).

- Colorfastness to Washing/Laundering: Determines if the color will bleed or fade during standard or commercial washing procedures (key for bedding, towels, and clothing).

- Colorfastness to Crocking (Rubbing): Assesses the transfer of dye from the surface of a colored fabric to an adjacent white fabric due to rubbing, both when dry and when wet (essential for upholstery testing).

- Dimensional Stability (Shrinkage): Quantifies the change in fabric size (shrinkage or growth) after exposure to washing and drying cycles or specific environmental conditions, ensuring a product fits its intended application after cleaning.

- Odor Assessment: Evaluating any lingering chemical or processing odors that might be off-putting to consumers, falling under the broader scope of material safety.

These tests provide objective data that helps manufacturers perfect their dyeing, printing, and finishing processes, guaranteeing that the aesthetic appeal and fit of the product last throughout its functional life.

Navigating Global Regulatory Compliance and Consumer Safety

The globalized supply chain means that a single product may need to comply with a patchwork of national and regional regulations. Effective home textile testing is not just about isolated performance checks; it is about establishing a holistic compliance strategy that anticipates the requirements of every target market.

For furniture testing and home textile testing, navigating compliance requires knowledge of major acts and directives:

- United States: Requires compliance with CPSC (Consumer Product Safety Commission) regulations, including the Flammable Fabrics Act (FFA), which mandates specific tests for textiles and mattress flammability.

- European Union (EU): Requires adherence to directives like REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), which strictly controls the chemical substances in products, and various national fire safety codes (e.g., in the UK or France).

- Canada: Health Canada regulations govern various aspects of consumer safety, including hazardous products and specific flammability requirements.

- California Proposition 65 (Prop 65): Although a state regulation, it significantly impacts the US market, requiring warnings for products containing chemicals known to cause cancer or reproductive toxicity, necessitating precise material safety analysis.

A specialized contract laboratory partner can offer the expertise needed to map a product’s materials against the required standards for each market, providing the necessary documentation and certification reports. This strategic approach minimizes compliance risk and streamlines the process of bringing new products to diverse international shelves, ultimately safeguarding consumer safety on a global scale.

Elevate Product Quality: Your Next Step in Home Textile Testing and Compliance

The landscape of home textile and furnishing compliance is intricate, demanding continuous vigilance across flammability, chemical safety, durability, and aesthetics. The high stakes—including brand reputation, costly litigation, and, most importantly, consumer safety—necessitate a commitment to rigorous, independent home textile testing. By prioritizing comprehensive testing protocols that include mattress flammability and thorough material safety screenings, your operations can move beyond merely meeting the minimum standards to establishing a benchmark for product excellence and global compliance. Don’t let testing capacity or complexity become a bottleneck for market entry or product innovation.

Submit a testing request today to secure brand integrity, ensure global market access, and protect consumer safety through expert, accredited laboratory outsourcing for all your furniture testing and textile needs.

FAQ

The most critical compliance test for mattresses in the U.S. is the full-scale open-flame test mandated by 16 CFR Part 1633 (Standard for the Flammability of Mattress Sets). This rigorous mattress flammability test ensures the product resists ignition and limits the rate of heat release, making it essential for consumer safety.

How does REACH regulation impact my furniture testing program?

Wyzenbeek and Martindale testing are both methods for measuring the abrasion resistance of fabric, a key durability metric in upholstery testing. They simulate wear and tear to predict how long a fabric will last before showing noticeable wear, helping manufacturers determine the appropriate end-use classification for the fabric.

Third-party home textile testing provides independent, unbiased verification of quality and compliance. This not only fulfills regulatory requirements but also provides credible assurance to consumers and retailers, mitigating the risk of product failure, enhancing brand trust, and demonstrating a strong commitment to consumer safety and material quality.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.