The release of the 2025–2030 Dietary Guidelines for Americans (DGAs) in January 2026 has done more than update a food pyramid. Arriving simultaneously with the strict enforcement of the FDA’s “Closer to Zero” initiative for toxic elements, the food and beverage industry now faces a regulatory paradox. On one hand, federal nutritional advice has become increasingly complex and, at times, contradictory. On the other, the technical standards for chemical safety—specifically for lead, arsenic, and cadmium—have tightened to single-digit parts-per-billion (ppb) levels.

For the third-party testing, inspection, and certification (TIC) sector, this marks the end of the commodity testing era. Laboratories are no longer just checking boxes; they are essential partners in a high-stakes environment where verification at scale is the only defense against regulatory action and consumer skepticism.

The DGA Paradox: Nutritional Ambiguity versus Quantitative Rigor

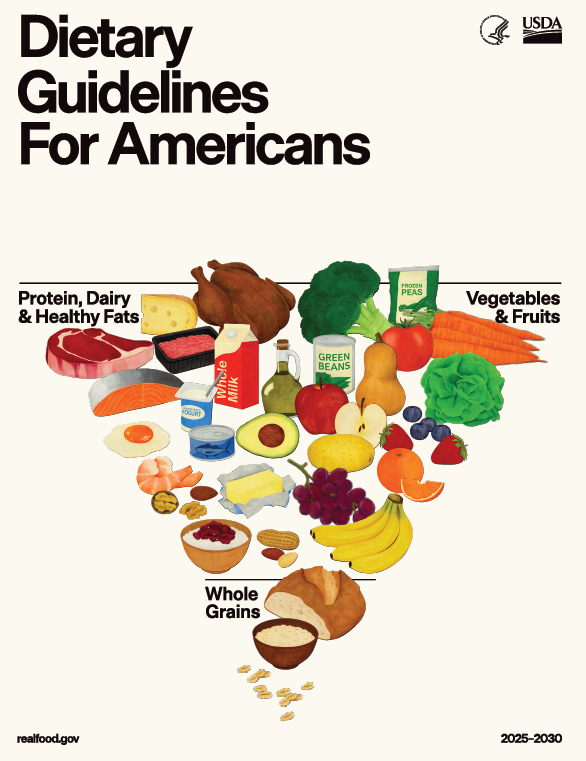

The 2025-2030 DGAs present a distinct regulatory gap between their visual advice and their quantitative text. Navigating this gap requires precise analytical testing to substantiate label claims that might otherwise be deemed misleading.

The visual new food pyramid prominently features red meat and full-fat dairy, yet the textual guidelines explicitly cap saturated fat at 10% of total daily calories. “The inverted pyramid thus seems to be an attempt to convey the goal of flipping nutrition guidance on its head… rather than a tool to help consumers understand how to eat healthier,” wrote Susan Mayne, PhD, professor (adjunct) at the Yale School of Public Health, CT, in a recent piece, shedding light on the ambiguity of the food pyramid imagery.

Manufacturers following the visual guide, too, may inadvertently exceed the quantitative limits. To mitigate legal risk, brands must move beyond basic calculation-based labeling to rigorous analytical verification.

Lipid Profiling (AOAC 996.06) has become essential for determining the exact ratio of saturated to unsaturated fats in reformulated products. Similarly, with the continued focus on heart health, precise Cholesterol Analysis (AOAC 994.10) via gas chromatography with flame ionization detection (GC-FID) is now required to substantiate “heart-healthy” claims on animal-based products that sit in this gray area.

The Essential Error and the Fiber Gap

Researchers from the Harvard T.H. Chan School of Public Health have noted several contradictions in the new guidelines: the implication that animal fats like butter and tallow are adequate sources of “essential fatty acids” (EFAs). In reality, plant oils are better sources of EFAs and more heart-healthy.

This error creates a marketing opening for plant-based brands. Laboratories can now pitch fatty acid profiling to analytically demonstrate the superior EFA content of plant oils compared to DGA-endorsed dairy fats, providing the data needed for “good source” claims that contradict the pyramid’s visual narrative.

Furthermore, while the DGAs focus heavily on protein, the Academy of Nutrition and Dietetics has emphasized the often-overlooked role of the microbiome. This signals a rising demand for Prebiotic Fiber Analysis (AOAC 2009.01) as brands formulate to support gut health—a key consumer driver that the federal guidelines largely downplayed.

Closer to Zero: The Technical Shift to ICP-MS

While the nutritional guidelines debate philosophy, the FDA’s Closer to Zero initiative is a hard-edged enforcement reality. As of 2026, the finalized action levels for lead in baby foods have fundamentally altered the laboratory infrastructure required for compliance.

The FDA has set a 10 ppb (parts per billion) action level for lead in fruits, vegetables, mixtures, and yogurts intended for infants. To put this in perspective, 10 ppb is roughly equivalent to ten drops of water in an Olympic-sized swimming pool.

| Food Category | Action Level (ppb) | Compliance Implication |

| Fruits & Vegetables (excluding single-ingredient root crops) | 10 ppb | Requires strict water quality control and soil selection. |

| Mixtures (grain, meat, or vegetable-based blends) | 10 ppb | Any ingredient (e.g., spice mix) can cause failure. |

| Yogurts, Custards, Puddings | 10 ppb | Dairy sourcing is critical; processing equipment must be lead-free. |

| Single-Ingredient Meats | 10 ppb | Bioaccumulation in animal organs must be monitored. |

| Single-Ingredient Root Vegetables (Carrots, Sweet Potatoes, Beets) | 20 ppb | Acknowledges soil uptake challenges but remains strict. |

| Dry Infant Cereals | 20 ppb | Requires clean grain sourcing (e.g., low-lead oats/rice). |

This ultra-low limit has rendered Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) largely obsolete for this category. Historically, the workhorse for heavy metals, ICP-OES typically has a Limit of Quantitation (LOQ) around 30-50 ppb for complex food matrices. Using OES for baby food testing is now a liability; a “Not Detected” result often means “less than 50 ppb,” which fails to prove compliance with a 10 ppb limit.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is now the only viable technology for the 2026 landscape, offering sensitivity in the parts-per-trillion (ppt) range. This shift demands significant operational upgrades, including ISO Class 6 or 7 cleanrooms to prevent airborne dust contamination and the use of trace metal grade reagents to avoid false positives.

Ultra-Processed Foods: Testing for the “Invisible”

While the DGAs stopped short of formally adopting the NOVA classification system, the recommendation to limit “highly processed foods” has accelerated the anti-ultra-processed food, or anti-UPF, movement. Since there is no “UPF Detector,” laboratories are developing panels to detect biomarkers of ultra-processing.

Retailers and clean-label certifications are increasingly demanding proof that products are free from industrial markers. This includes cosmetic additives screening via LC-MS/MS for synthetic colors (like Red 40 and Yellow 5) and flavor enhancers.

Beyond ingredients, the focus has shifted to processing intensity. Testing for furan and acrylamide—contaminants formed during high-heat industrial processing like extrusion—now serves as a chemical proxy for ultra-processing. Additionally, high-sensitivity testing for glyphosate residue is becoming a standard requirement for oat- and wheat-based products seeking “Clean” status.

The Digital Thread: FSMA 204 and Traceability

The analytical result is only half the deliverable. Under FSMA 204 (The Food Traceability Rule), fully effective in 2026, data integrity and transferability are paramount.

For high-risk foods on the Food Traceability List (FTL)—such as nut butters, soft cheeses, and leafy greens—the Certificate of Analysis (CoA) effectively functions as a Key Data Element. Laboratories must transition away from PDF reporting. Manufacturers now require data in structured formats (XML, JSON) that can be instantly ingested into ERP or Blockchain traceability systems. Labs that cannot offer API integration will struggle to retain enterprise clients.

Furthermore, the FDA’s Laboratory Accreditation for Analyses of Foods (LAAF) program has become the gatekeeper for regulatory testing. Any testing to support removal from an Import Alert or in response to a Food Safety Order must be conducted by a LAAF-accredited body, creating a distinct tier of laboratories capable of handling high-stakes regulatory work.

Strategic Outlook: The Laboratory as a Competitive Advantage

In the 2026-2030 cycle, the laboratory is the bridge between conflicting regulations and consumer trust. For manufacturers, the era of “trust me” marketing is over. Claims must be verified by independent data that withstands scrutiny from both the FDA and academic critics.

Manufacturers must audit their testing portfolios to ensure they aren’t carrying unmeasured risk by using outdated methods like ICP-OES for sensitive categories. For laboratories, the value lies not just in the data point, but in the ability to interpret that data against a backdrop of contradictory federal advice.

Take Action with Contract Laboratory

Whether you are a manufacturer navigating the 10 ppb-lead limit or a laboratory looking to fill your ICP-MS capacity, Contract Laboratory is the central hub for scientific outsourcing. Register your lab and come join the global network.

And if you need urgent heavy metals testing, nutritional profiling, or other related analyses, submit a lab request right away and get free quotes from accredited labs.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.