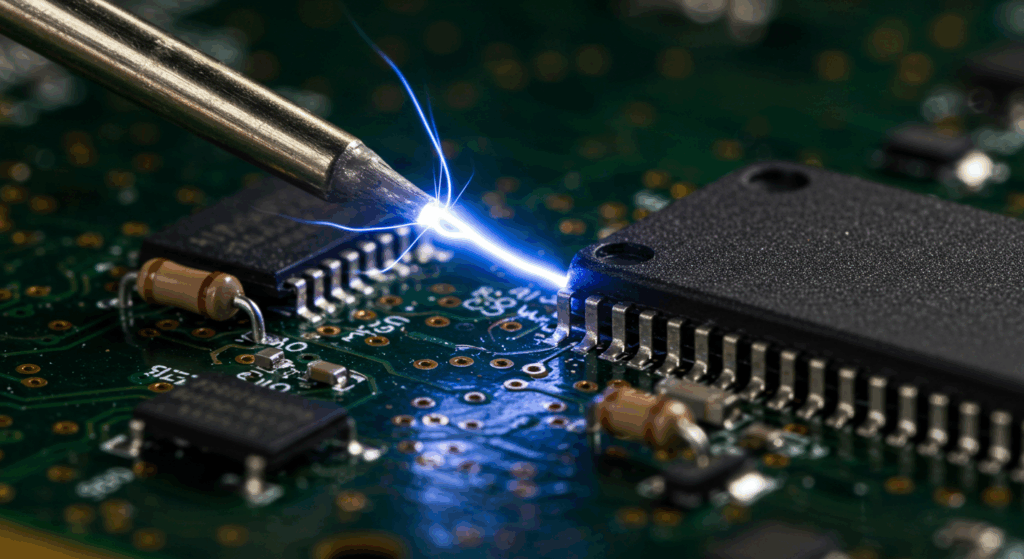

In the fast-paced world of electronics, where miniaturization and complexity are ever-increasing, invisible threats can cause significant damage and costly failures. Electrostatic Discharge (ESD), the sudden flow of electricity between two electrically charged objects, is one such silent destroyer. Electrostatic Discharge (ESD) Testing is therefore not merely a recommendation but a critical imperative for device protection, ensuring ESD safety, bolstering product reliability, and safeguarding sensitive electronics components. This article delves into the crucial role of Electrostatic & Discharge (ESD) Testing in preventing damage, validating component protection, and maintaining overall product reliability in the manufacturing and operational life of electronic devices.

Electrostatic Discharge (ESD) Testing: Ensuring ESD Safety

ESD safety is foundational to any environment where sensitive electronics are handled, manufactured, or tested. An uncontrolled ESD event, even one imperceptible to humans (which can feel a static shock only above 3,000 volts), can generate thousands of volts, enough to severely damage or destroy microelectronic components. Implementing rigorous Electrostatic & Discharge (ESD) Testing protocols is key to identifying vulnerabilities and ensuring a protective environment. This proactive approach focuses on mitigating risks from both direct human contact and charged equipment, providing essential device protection.

Key aspects of ensuring ESD safety include:

- ESD Protected Areas (EPAs): Designated zones equipped with ESD-safe flooring, workstations, grounding systems, and humidity control to prevent charge buildup.

- Personnel Grounding: Use of wrist straps, heel straps, and ESD-safe footwear to safely dissipate static charges from personnel.

- ESD-Safe Tools and Materials: Utilizing tools, packaging, and handling materials (e.g., trays, bags) that are made from dissipative or conductive materials.

- Training and Awareness: Educating personnel on ESD principles, potential risks, and proper handling procedures.

Regular Electrostatic & Discharge (ESD) Testing of these ESD safety measures, such as surface resistivity measurements and continuity checks of grounding systems, ensures their continued effectiveness in preventing ESD events.

Electrostatic Discharge (ESD) Testing: Validating Component Protection

The core objective of Electrostatic Discharge (ESD) Testing is to validate the effectiveness of component protection mechanisms built into electronics devices. Modern integrated circuits (ICs) and other sensitive components incorporate on-chip ESD protection structures, but these require thorough testing to confirm their robustness against real-world ESD events. This rigorous electrical testing assesses how well a device can withstand various ESD stresses without incurring damage, directly contributing to product reliability.

Common ESD stress models used in electrical testing for component protection include:

- Human Body Model (HBM): Simulates the discharge from a charged human body to a device. This is one of the most widely used tests, typically involving voltages ranging from ±250V to ±8000V.

- Machine Model (MM): Represents the discharge from a charged machine or tool, characterized by a lower resistance and faster discharge time compared to HBM. MM testing is usually performed at lower voltages, e.g., ±200V to ±400V.

- Charged Device Model (CDM): Simulates a device becoming charged and then discharging to a grounded surface, which is a common occurrence during automated manufacturing. CDM events are very fast and high current, often causing localized damage. Testing ranges from ±100V to ±1500V.

- Transmission Line Pulse (TLP): A more advanced characterization technique that applies precisely controlled, short-duration voltage pulses to components to evaluate their ESD protection circuitry’s performance and failure threshold.

These electrical testing methods help engineers design more robust components and ensure effective device protection against various ESD scenarios encountered during handling, assembly, and end-use.

Electrostatic Discharge (ESD) Testing: Ensuring Product Reliability

Beyond individual component resilience, Electrostatic Discharge (ESD) Testing is paramount for overall product reliability. An ESD event might not cause immediate catastrophic failure but can lead to latent defects, where a component is weakened and fails prematurely in the field, leading to costly warranty claims, recalls, and reputational damage. Comprehensive electrical testing at the system level helps identify these vulnerabilities, ensuring the long-term performance and durability of electronics.

Aspects of Electrostatic Discharge (ESD) Testing for product reliability include:

- System-Level ESD Testing: Applying ESD pulses directly to the product’s accessible surfaces (e.g., buttons, ports, chassis) to simulate real-world electrostatic interactions. Standards like IEC 61000-4-2 are commonly used for this.

- Transient Latch-up Testing: Assessing whether ESD events cause undesired functional anomalies or permanent damage in CMOS integrated circuits due to parasitic structures.

- Electromagnetic Compatibility (EMC) Testing: While broader than ESD, EMC testing often includes ESD immunity tests as a subset, ensuring the product functions correctly in its electromagnetic environment.

- Failure Analysis: Post-test examination of damaged components using techniques like SEM (Scanning Electron Microscopy) or Liquid Crystal Thermography to identify the precise ESD failure mechanism and inform design improvements.

By thoroughly testing finished electronics products, manufacturers can significantly enhance their product reliability and reduce the risk of field failures attributed to ESD.

Finding the Right Lab for Your Electrostatic Discharge (ESD) Testing Needs

The increasing sophistication of electronics demands equally sophisticated approaches to device protection. Comprehensive Electrostatic Discharge (ESD) Testing is a non-negotiable step in ensuring ESD safety, validating component protection, and guaranteeing overall product reliability. From intricate electrical testing at the component level to rigorous system-level evaluations, partnering with the right laboratory is essential for navigating these complex requirements and mitigating the silent threat of ESD.

If your company requires specialized Electrostatic Discharge (ESD) Testing services or needs to find a qualified laboratory to ensure the robustness and reliability of your electronics products, Contract Laboratory can assist. We connect businesses and individuals with a global network of accredited third-party laboratories. These labs possess the cutting-edge instrumentation and expertise to handle the intricate demands of ESD analysis, helping you achieve consistent quality, regulatory compliance, and build lasting customer confidence. Submit a Testing Request Today!