In any manufacturing or research environment, the integrity of a material is paramount. Before advanced analytical techniques like SEM and XRF are employed, the very first step in ensuring quality is often the simplest and most fundamental: visual inspection. This is a non-destructive process that uses the human eye, often assisted by optical aids, to assess a material’s surface and internal characteristics. While it may seem straightforward, a thorough visual and optical inspection can be the most effective and cost-efficient method for early defect detection, preventing costly failures down the line.

This article explores the critical role of visual and optical inspection, with a particular focus on its application in materials like glass. We will delve into how to identify common flaws, from surface scratches to internal stress patterns, and how these techniques form the foundation of a robust quality control program.

Why Visual and Optical Inspection Are Essential for Quality Control

Visual inspection is the cornerstone of any effective quality control system. It is a rapid, non-destructive method used to identify and classify imperfections in materials and products. For many industries, from automotive to aerospace, it is a required step in verifying product conformance. When performed by a trained professional, it can uncover a wide range of issues that might otherwise go unnoticed, from cosmetic blemishes to critical structural flaws.

This process is not limited to what is visible to the naked eye. Optical inspection uses tools like magnifying glasses, stereoscopes, and video microscopes to enhance the analyst’s ability to see and characterize tiny defects. This combination of human expertise and optical technology allows for a high degree of precision in defect detection.

Key applications of visual and optical inspection include:

- Surface Finish: Assessing the smoothness, texture, and presence of scratches, nicks, or pits.

- Dimensional Accuracy: Verifying that a component’s size and shape conform to engineering drawings.

- Assembly Integrity: Ensuring all components are correctly installed and that there are no gaps or misalignment.

- Aesthetic Quality: Checking for discoloration, bubbles, or other aesthetic flaws that may affect a product’s marketability.

The effectiveness of these techniques is particularly evident in the highly sensitive field of visual inspection, where even the smallest imperfection can compromise a product’s performance or safety.

Defect Detection in Glass: Common Flaws and Inspection Techniques

Glass is a fascinating material to inspect due to its transparency and the variety of defects it can contain. A comprehensive visual inspection protocol involves looking for both surface and internal flaws. Surface flaws, such as scratches or cracks, can be a point of stress concentration, potentially leading to catastrophic failure. However, the most critical defects in glass often lie beneath the surface, requiring optical inspection to be properly identified.

Common defects in glass include:

- Bubbles: Gas pockets trapped within the glass. These can be tiny and scattered or large and concentrated. Their analysis is often referred to as bubble analysis. While small bubbles can be an aesthetic concern, larger bubbles can weaken the material and are often a sign of an issue in the manufacturing process.

- Stones: Undissolved raw materials or refractory particles in the glass. These solid inclusions can create stress points, making the glass more susceptible to thermal shock or impact.

- Knots: Inhomogeneities in the glass composition, often appearing as streaks or swirls. They can affect the optical clarity and uniformity of the material.

- Birefringence: An optical phenomenon where a material has a refractive index that depends on the polarization and propagation direction of light. In glass, it is a key indicator of internal stress patterns.

The combination of skilled visual observation and specialized tools is essential for effective defect detection in materials like glass.

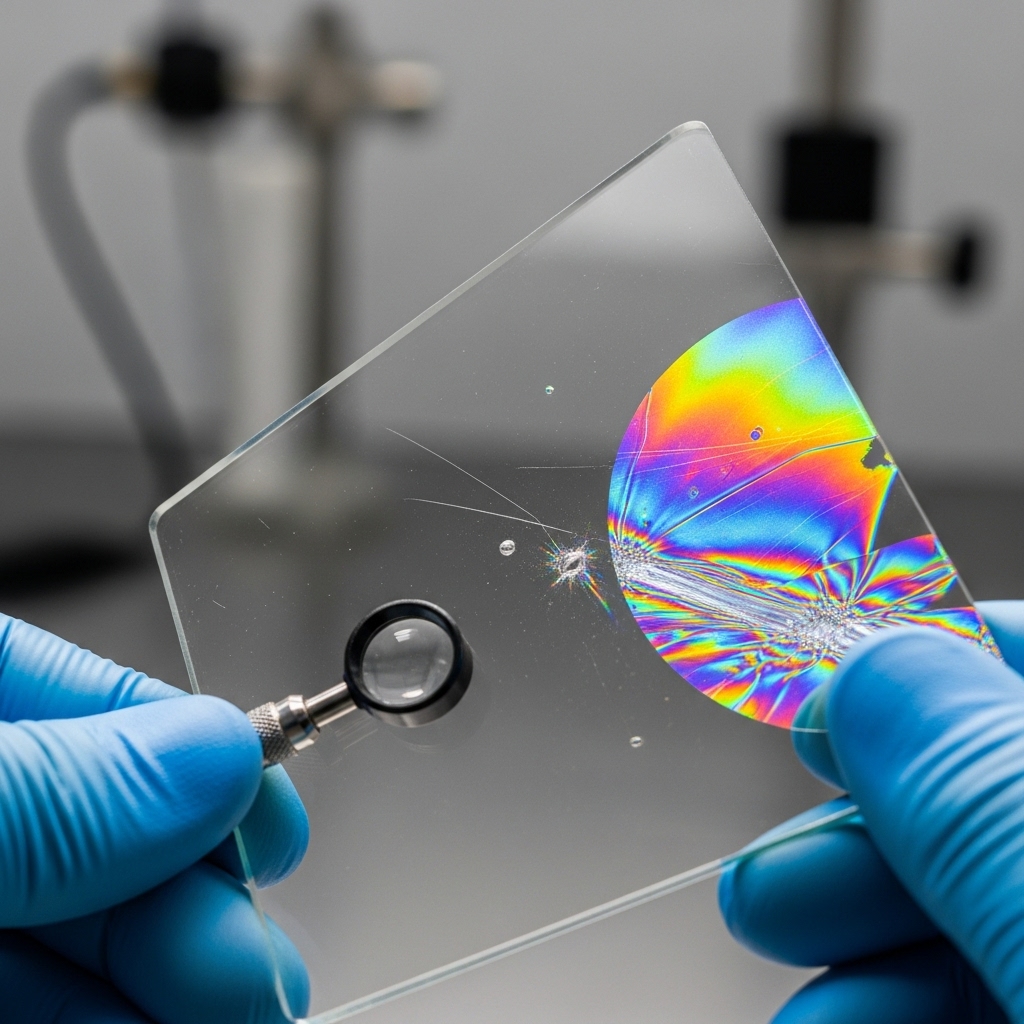

Understanding Birefringence: Detecting Stress Patterns Through Optical Inspection

One of the most powerful and often overlooked aspects of optical inspection is the detection and analysis of stress patterns within transparent materials, a phenomenon known as birefringence. When glass is improperly cooled (a process called annealing), residual stresses can build up within the material. These stresses, while invisible to the naked eye, can significantly reduce the material’s strength and make it vulnerable to fracture.

Birefringence can be observed using a polarimeter, or a simple cross-polarizer setup. When polarized light passes through stressed glass, the stress patterns cause the light to split and re-combine, creating a visually stunning array of colors. The colors and their intensity are directly related to the magnitude of the stress in the glass. By analyzing these patterns, an inspector can determine if the glass has been properly annealed and is fit for its intended use. This type of stress detection is a crucial part of quality control for products ranging from consumer glassware to sophisticated optical lenses. It is a perfect example of how optical inspection goes far beyond simple surface checks.

The Strategic Importance of Visual Inspection for Quality Control

While advanced analytical methods provide deep insights into a material’s chemical and structural composition, they often require extensive sample preparation and can be time-consuming and costly. Visual inspection, supplemented by optical tools, offers a fast, affordable, and effective first line of defense for quality control. It is the essential starting point for identifying issues and can help guide more in-depth analyses.

By implementing a rigorous program of visual inspection and optical inspection, manufacturers can reduce waste, improve product reliability, and ultimately strengthen their brand reputation. The ability to quickly perform defect detection, from simple flaws to complex stress patterns, ensures that only the highest quality products reach the market.

Submit a testing request today to find a lab that specializes in visual and optical inspection to enhance your quality control processes.

Frequently Asked Questions

The main purpose of visual inspection is to quickly and non-destructively identify any visible flaws or defects in a material, ensuring it meets specified quality control standards before it is used or sold.

Bubble analysis is typically performed as part of an optical inspection. Analysts use magnification to count, measure, and characterize bubbles within a material like glass, helping to assess the material’s quality and identify potential manufacturing issues.

While residual stress patterns indicated by birefringence are often undesirable in glass due to the risk of fracture, controlled birefringence is a desired property in some optical components and can even be an intentional part of a material’s design.

No, visual inspection serves as a complementary step. It helps identify a problem and guide the need for more in-depth analyses. For complex issues, a full material characterization using methods like SEM/EDS is still necessary.

This content includes text that has been generated with the assistance of AI. Contract Laboratory encourages the use of new tools and technologies that enhance our editorial process. Our full editorial policy can be found here.