In the complex landscape of food safety, manufacturers and distributors must navigate a myriad of regulations to protect public health. While attention often focuses on the food itself, the containers and utensils we use to store, prepare, and consume food are equally critical. Glass and ceramic materials, ubiquitous in our kitchens and industrial settings, present a unique set of challenges. These materials, seemingly inert and safe, can harbor “unseen threats” in the form of heavy metals and other chemical compounds that can leach into food and beverages. The need for rigorous, proactive testing is not merely a legal obligation but a cornerstone of consumer trust and brand integrity.

For laboratories specializing in materials and analytical chemistry, understanding these threats is paramount. The rise of global supply chains means that products from diverse manufacturing origins must all meet stringent international and national standards. This article will explore the critical principles behind food contact glass testing and ceramic analysis, detailing the risks, the required testing methodologies, and the regulatory frameworks that govern this essential aspect of public health. By equipping yourself with this knowledge, you can ensure that the materials you produce or analyze are not just functional and beautiful, but also unequivocally safe.

Understanding the Risks: Why Food Contact Glass Testing is Non-Negotiable

The primary threat posed by glass and ceramic food contact materials lies in their potential to release harmful chemicals through a process known as chemical leaching, or migration. While glass is often considered stable, certain types and manufacturing processes can introduce trace amounts of elements that, under specific conditions, can migrate from the material’s surface into food. Similarly, ceramics, particularly those with decorative glazes, are a well-documented source of heavy metal contamination.

The process of leaching is not random; it is influenced by several key factors:

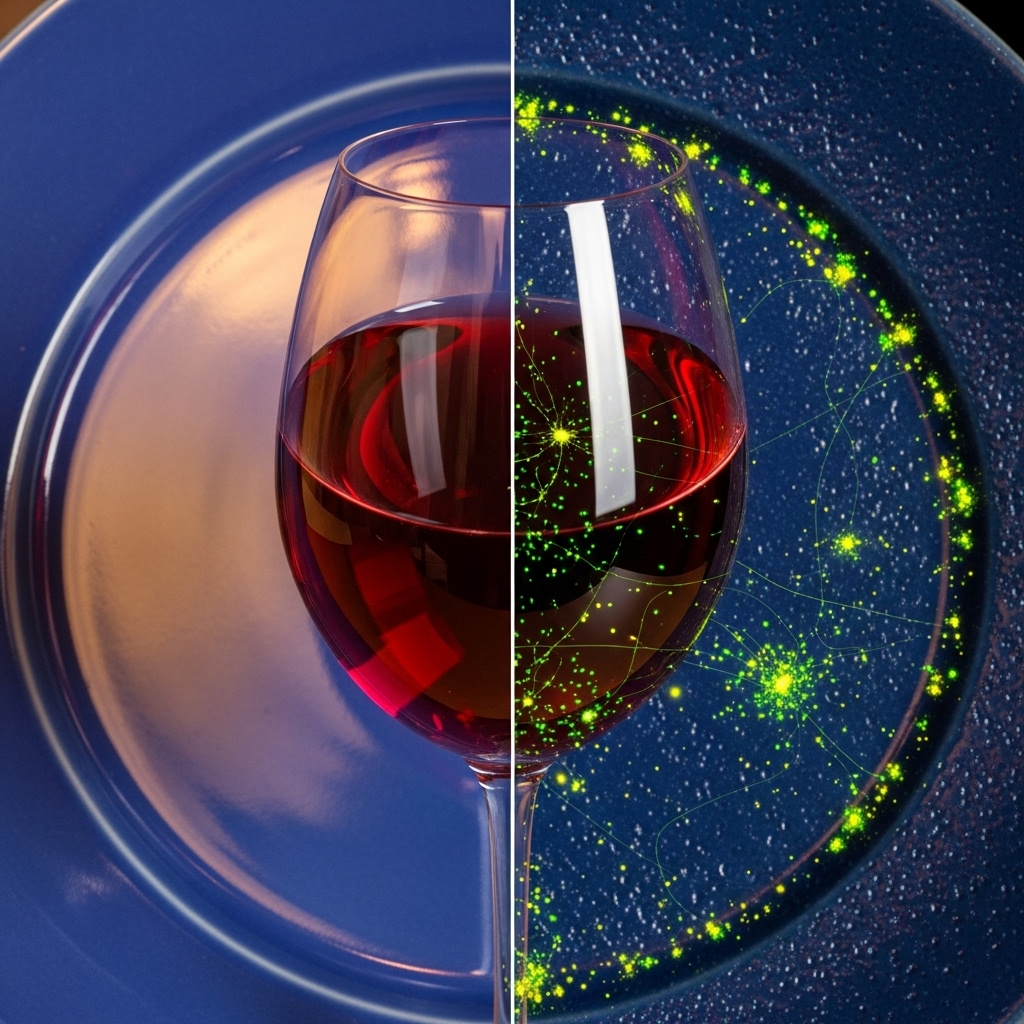

- Acidity of Food: Acidic foods and beverages (e.g., tomato sauce, fruit juices, wine, coffee) are far more likely to accelerate the leaching of heavy metals from glazes and glass matrices. The acid acts as a solvent, breaking down the chemical bonds that hold these elements in place.

- Temperature: Elevated temperatures, such as those experienced during cooking or when hot liquids are served, increase the kinetic energy of molecules, significantly enhancing the rate of chemical migration.

- Time: The duration of contact between the food and the material is a critical variable. Prolonged storage of food in a container, for example, increases the cumulative amount of leached chemicals.

- Material Composition: The raw materials used, the firing temperature of ceramics, and the presence of decorative components or colorants all directly impact the risk profile. For instance, brightly colored glazes, especially reds and yellows, have historically been a common source of lead and cadmium due to the pigments used.

Food contact glass testing is the scientific process of simulating these real-world conditions in a controlled laboratory environment. By exposing the material to standardized solvents (often dilute acidic solutions) and then analyzing the resulting extract, laboratories can quantify the amount of harmful substances that may migrate into food, ensuring the product’s safety.

The Dangers of Lead and Cadmium in Ceramic Dinnerware

Among the most notorious “unseen threats” in food contact materials are lead and cadmium. Both are heavy metals with significant toxicological profiles, and their presence in ceramic dinnerware has been a major focus of food safety regulations for decades.

Lead, in particular, has long been a component of ceramic glazes, prized for its ability to produce a smooth, shiny, and durable finish. However, its toxicity is well-established. Even at low levels, chronic exposure to lead can cause a range of serious health problems, including:

- Neurological damage, particularly in children and developing fetuses, leading to learning disabilities and developmental delays.

- Kidney damage and hypertension in adults.

- Digestive issues and reproductive problems.

Cadmium, often used in vibrant pigments (especially reds, yellows, and oranges), is another heavy metal of concern. It is a known carcinogen and can accumulate in the human body, primarily in the kidneys and liver. Long-term exposure to cadmium can lead to:

- Kidney disease.

- Bone demineralization.

- Lung and prostate cancer.

The importance of lead and cadmium testing cannot be overstated. Manufacturers must demonstrate through certified laboratory testing that their products do not release these metals above established regulatory limits. This is especially crucial for ceramic dinnerware that is handmade, imported from regions with less stringent oversight, or decorated with vibrant glazes, where the risk of improper firing or low-quality raw materials is higher.

Navigating Regulatory Compliance: A Global Perspective

For manufacturers and suppliers operating in a global market, understanding and complying with the diverse and evolving regulations for food contact materials is a major challenge. Regulatory bodies around the world have established specific limits for the acceptable migration of heavy metals from glass and ceramic products.

- United States: The U.S. Food and Drug Administration (FDA) has specific policies for ceramicware, which classify products based on their use (e.g., cups, plates, large bowls). The FDA’s test method involves a 24-hour leach with a 4% acetic acid solution, followed by a quantitative analysis of the extract. The compliance limits are specified in milligrams of lead or cadmium per liter of the extract, varying by the type of product.

- European Union: The EU has a comprehensive framework, including Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food. For ceramics, specific migration limits are set in Directive 84/500/EEC, which is now incorporated into Regulation (EC) No 1935/2004. Similar to the FDA, the EU uses a leaching test with 4% acetic acid, but the limits are generally more stringent and apply to a wider range of elements, ensuring robust food safety.

- Other Regions: Countries in Asia, South America, and elsewhere have their own national standards, which may or may not align with U.S. or EU regulations. Japan, for example, has strict standards under the Food Sanitation Law. The complexity of this global regulatory landscape underscores the need for expert food contact glass testing and lead and cadmium testing services to ensure products can be legally sold in multiple markets.

Compliance is not a one-time event. Changes in regulations, new scientific findings, or modifications to a product’s manufacturing process all necessitate re-evaluation and re-testing. Partnering with a lab network that is up-to-date on global standards is an invaluable asset for maintaining regulatory compliance.

The Path to Proactive Food Safety: Advanced Analytical Techniques

Accurate and reliable testing is the bedrock of ensuring the food safety of glass and ceramic materials. The methods used in modern laboratories are highly sensitive and capable of detecting even trace amounts of heavy metals. The most common and effective techniques include:

- Inductively Coupled Plasma – Optical Emission Spectrometry (ICP-OES): This is a powerful multi-element analysis technique. A sample is introduced into an argon plasma, which excites the atoms. As the atoms return to a lower energy state, they emit light at characteristic wavelengths. The intensity of this light is directly proportional to the concentration of the element in the sample. ICP-OES is highly sensitive, fast, and can simultaneously measure a wide range of elements, making it ideal for comprehensive food contact glass testing.

- Atomic Absorption Spectroscopy (AAS): AAS is another widely used method for elemental analysis. It measures the concentration of a specific element by analyzing the light absorbed by the atomized sample. While it is generally a single-element technique, newer systems can analyze multiple elements sequentially. It is often used for targeted lead and cadmium testing due to its high sensitivity for these specific elements.

- X-ray Fluorescence (XRF): XRF is a non-destructive screening method that can quickly identify and quantify elemental composition on the surface of a material. While it is not a direct leaching test, it can be an effective initial screening tool for ceramic dinnerware to identify the presence of heavy metals in glazes before a more rigorous leaching test is performed.

The choice of method depends on the specific regulatory requirements and the elements of concern. A reputable testing partner will be able to recommend the most appropriate analytical approach to meet your specific needs for regulatory compliance. These advanced techniques provide the precision and accuracy necessary to safeguard public health and ensure products are market-ready.

Conclusion: Securing Food Safety Through Rigorous Testing

The safety of glass and ceramic dinnerware is a complex and crucial aspect of food safety that demands constant vigilance. From the subtle process of chemical leaching to the well-documented dangers of lead and cadmium, the threats are real and require a professional, scientific approach. Through comprehensive food contact glass testing and advanced analytical methods like ICP-OES and AAS, manufacturers and labs can confidently ensure their products meet the highest standards of regulatory compliance and consumer safety.

By prioritizing proactive testing and partnering with a network of qualified laboratories, businesses can mitigate risk, protect their brand, and play a vital role in protecting public health.

Submit a testing request today to connect with a global network of accredited labs and ensure your glass and ceramic food contact materials are safe and compliant.

Frequently Asked Questions

The primary purpose is to determine if harmful chemicals, particularly heavy metals like lead and cadmium, can leach from the glass or ceramic material into food and beverages under normal use conditions, thereby ensuring consumer food safety and regulatory compliance.

Lead and cadmium testing is critical because these heavy metals are highly toxic and have been historically used in ceramic glazes. Leaching of these elements can cause serious health issues, making their detection and quantification a non-negotiable step for all ceramic dinnerware sold globally.

Laboratories simulate chemical leaching by exposing the product to an acidic solution (most commonly 4% acetic acid) for a specific period, typically 24 hours. The resulting solution, called the extract, is then analyzed to measure the concentration of any leached heavy metals.

The most important regulations for food safety depend on the target market. Key regulatory bodies include the U.S. FDA, the European Union (EU), and various national agencies. Compliance with these standards requires specialized food contact glass testing to ensure products are fit for sale.

This content includes text that has been generated with the assistance of AI. Contract Laboratory encourages the use of new tools and technologies that enhance our editorial process. Our full editorial policy can be found here.