Introduction to Motion & Dynamic Forces Analysis

In today’s competitive landscape, product reliability is paramount. Motion and Dynamic Forces Analysis is a critical field of engineering and testing that evaluates how a product or material responds to external forces and movements. Unlike static testing, which measures an object’s response to a constant load, dynamic analysis assesses performance under conditions that change over time. This includes forces such as vibration testing, shock testing, and cyclic loads that lead to fatigue testing. Understanding these dynamic responses is essential for ensuring a product’s structural dynamics, product durability, and overall performance, especially in industries like aerospace, automotive, electronics, and consumer goods.

Key Subtopics of Motion & Dynamic Forces Analysis

Vibration Testing: Simulating Movement with Motion & Dynamic Forces Analysis

Vibration testing is the process of subjecting a product to an oscillatory motion to simulate the environmental conditions it will experience during its lifecycle. This can include vibrations from an engine, transportation, or natural phenomena. The goal is to identify resonant frequencies, pinpoint structural weaknesses, and evaluate the product’s ability to withstand continuous motion without failure.

Types of Vibration Testing

- Sine Vibration: A test where a product is subjected to a single frequency that sweeps across a defined range. Useful for identifying resonant frequencies.

- Random Vibration: A more realistic test that exposes the product to a broad range of frequencies simultaneously, mimicking real-world environments.

- Shock and Drop Testing: Used to simulate sudden, high-magnitude impacts.

Shock Testing: Impact Resistance Through Motion & Dynamic Forces Analysis

Shock testing measures a product’s ability to withstand sudden accelerations or impacts. A sudden impact can cause a product to fail in a different way than continuous vibration. Shock tests are crucial for products that may be dropped, involved in a collision, or subjected to explosive forces.

Shock Test Methods

| Method | Description | Common Application |

|---|---|---|

| Mechanical Shock | A controlled impact is applied using a shock machine. | Electronics, military equipment |

| Drop Test | The product is dropped from a specific height onto a hard surface. | Consumer packaging, mobile devices |

| Pyroshock | Simulates the high-frequency, high-magnitude shock caused by pyrotechnic devices. | Aerospace, satellite components |

Fatigue Testing: Evaluating Lifespan with Motion & Dynamic Forces Analysis

Fatigue testing is the process of applying cyclic or repeated loads to a material or component to determine its lifespan under these conditions. Over time, these repeated stresses can cause a product to fail at a stress level far below its ultimate tensile strength. Product durability is a direct result of passing these tests.

Key Concepts in Fatigue Testing

- Stress-Life (S-N) Curves: Graphs that plot stress amplitude against the number of cycles to failure.

- Fatigue Limit/Endurance Limit: The stress level below which a material can endure an infinite number of cycles without failure.

- Crack Propagation: Studying how tiny cracks form and grow under repeated stress.

Relevant Regulations and Testing Standards for Motion & Dynamic Forces Analysis

For lab technicians, scientists, and QA/QC managers, adhering to established regulations and standardized test methods is critical for ensuring product compliance and reliability. Here are some of the most widely used standards related to dynamic forces analysis across different industries:

- Military and Aerospace:

- MIL-STD-810: This is a U.S. military standard that is widely adopted for commercial and defense applications. It defines environmental engineering considerations and laboratory tests for a wide range of conditions. Key methods include:

- Method 514 (Vibration): Specifies various vibration testing procedures to simulate transport and operational conditions.

- Method 516 (Shock): Outlines procedures for testing a product’s ability to withstand sudden, non-periodic impacts.

- RTCA DO-160: A standard for airborne equipment, often used to certify avionics. It includes specific sections on vibration and shock testing to ensure equipment can operate safely in flight environments.

- MIL-STD-810: This is a U.S. military standard that is widely adopted for commercial and defense applications. It defines environmental engineering considerations and laboratory tests for a wide range of conditions. Key methods include:

- Automotive:

- ISO 16750 (Part 3): This international standard specifically addresses the mechanical loads (vibration, shock) on electrical and electronic equipment in road vehicles. It provides a comprehensive framework for testing components under realistic automotive conditions.

- SAE J1455: A set of recommended environmental practices for electronic equipment design in heavy-duty trucks, which includes protocols for dynamic testing.

- General Industrial & Electronics:

- IEC 60068: A series of international standards for the environmental testing of electronic and electrical products. Relevant parts include:

- IEC 60068-2-6: Defines methods for sinusoidal vibration testing.

- IEC 60068-2-27: Provides detailed procedures for shock testing.

- IEC 60068-2-64: Covers methods for broadband random vibration testing.

- ASTM Standards: The American Society for Testing and Materials publishes thousands of standards. ASTM E466 is a key standard for conducting constant-amplitude axial fatigue tests on metallic materials.

- IEC 60068: A series of international standards for the environmental testing of electronic and electrical products. Relevant parts include:

The Value of Third-Party Labs for Motion & Dynamic Forces Analysis

While in-house testing provides value, partnering with a third-party testing lab offers significant advantages, particularly for complex structural dynamics and product durability testing.

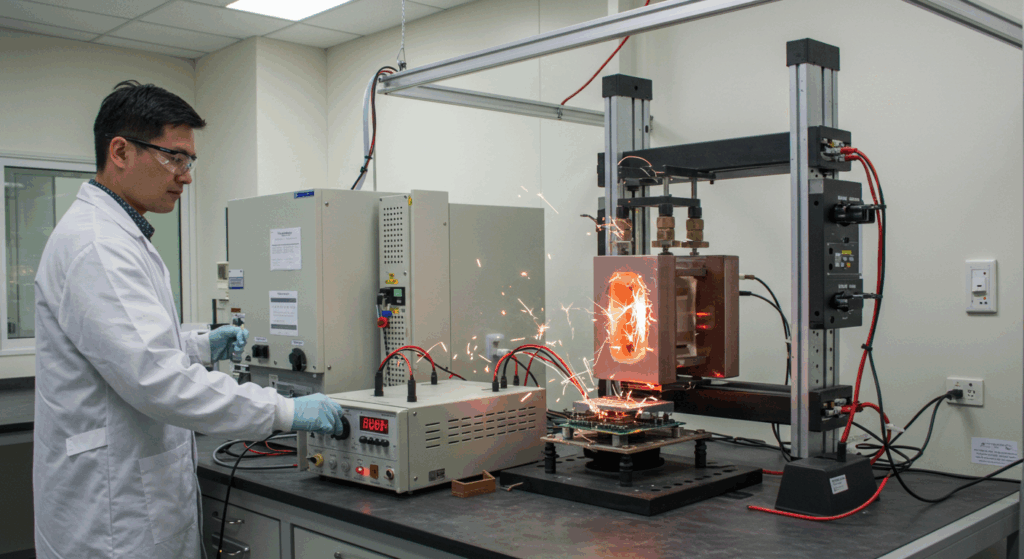

- Advanced Equipment and Expertise: Third-party labs have access to state-of-the-art equipment, such as electrodynamic shakers, drop towers, and advanced data acquisition systems, that may be too costly for a company to purchase and maintain. Their technicians are specialized experts in a wide range of testing standards and procedures.

- Unbiased Results: An independent third party provides objective, unbiased test results, which can be crucial for regulatory compliance, legal disputes, and demonstrating product quality to clients.

- Efficiency and Cost-Effectiveness: For many companies, outsourcing testing is more efficient and cost-effective than developing and staffing an in-house lab. It allows them to focus on core competencies while ensuring their products meet stringent quality standards.

- Certification and Compliance: Third-party labs often hold accreditations (like ISO/IEC 17025) and are experts in navigating complex industry standards (e.g., MIL-STD, ASTM, SAE), ensuring your product meets all required specifications.

Conclusion: A Foundation for Quality and Innovation

Motion & Dynamic Forces Analysis is more than just a quality control step; it is a fundamental part of the design and innovation process. By comprehensively testing for vibration, shock, and fatigue, companies can gain a deep understanding of their product’s behavior, leading to more robust designs, fewer product recalls, and enhanced customer trust. Leveraging the specialized capabilities of third-party testing labs allows businesses to confidently move from concept to market with products that are proven to be durable, reliable, and safe.

Ready to Ensure Your Product’s Durability?

Don’t leave product reliability to chance. If your project requires expert motion and dynamic forces analysis, including vibration, shock, or fatigue testing, submit a lab testing request to Contract Laboratory today. Our network of specialized labs is ready to provide the testing services you need to bring a robust, reliable product to market.